Rea u amohela liwebsaeteng tsa rona!

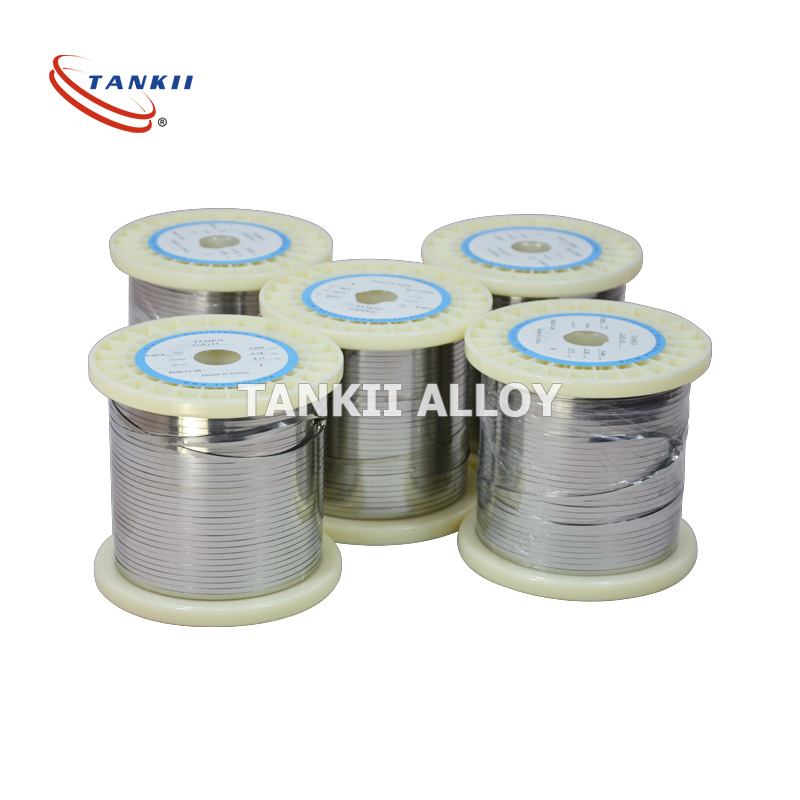

Terata e Khanyang ea 0.25mm 0Cr25Al5 ho ea ho Li-Furances tsa Liindasteri

Tlhahisoleseling ea Motheo.

| Paramethara | Lintlha tse qaqileng | Paramethara | Lintlha tse qaqileng |

|---|---|---|---|

| Nomoro ea mohlala. | 0cr25al5 | Sebopeho sa Lik'hemik'hale | 0cr25al5 |

| Lebitso la Sehlahisoa | Sekoahelo sa Khanyetso ea ho Futhumatsa | Litšobotsi | Ho hanyetsa ho hoholo, Oxidation e ntle Khanyetso |

| Mocheso o Phahameng ka ho Fetisisa oa Tšebeliso | 1300℃ | Botenya | 7.1g/cm³ |

| Ho tsitse ha mmele | 1.42 Ω·m | Ho lelefatsa | >20% |

| Mohlala | Tšehetso | Sephutheloana sa Lipalangoang | Likhechana tsa Lehong kapa Mabokose |

| Tlhaloso | 0.25mm | Letšoao la khoebo | Tankii |

| Tšimoloho | Jiangsu | Khoutu ea HS | 7408220000 |

| Bokgoni ba Tlhahiso | Lithane tse 100/Khoeli |

Tlhaloso ea Sehlahisoa

Terata ea 0.25mm 0cr25al5 ea Fecral Alloy e futhumatsang bakeng sa thapo ea ho hotetsa Tlhaloso e Akaretsang Motsoako oa FeCrAl o entsoe ka motswako oa ferritic iron-chromium-aluminium o mocheso o phahameng, o ka sebelisoang mochesong o fihlang ho likhato tse 1350. Ditshebediso tse tlwaelehileng bakeng sa FeCrAl ke dielemente tsa ho futhumatsa tsa motlakase ka diontong tse nang le mocheso o phahameng diindastering tsa ho phekola mocheso, tsa letsopa, tsa khalase, tsa tshepe le tsa elektroniki. Tšobotsi: Ka bophelo bo bolelele ba tšebeletso. E futhumatsa ka potlako. Bokgoni bo phahameng ba mocheso. Ho tšoana ha mocheso. E ka sebelisoa ka ho otloloha. Ha e sebelisoa ka motlakase o lekantsoeng, Ha ho na ntho e fetohang. Ke terata e futhumatsang ya motlakase e sireletsang tikoloho. Mme ke tsela e nngwe ho feta terata e turang ya nichrome. E ka etsoa ka mokhoa o ikhethileng ho latela litlhoko tsa bareki Li-alloy tsa FeCrAl li khetholloa ka ho hanyetsa ka mokhoa o motle oa oxidation le botsitso bo botle ba sebopeho bo fellang ka bophelo bo bolelele ba likarolo. Hangata li sebelisoa linthong tse futhumatsang motlakase liontong tsa indasteri le lisebelisoa tsa lapeng. Motsoako oa Fe-Cr-Al o nang le resistivity e phahameng le mocheso o sebetsang ho feta oa motsoako oa NiCr 'me o boetse o na le theko e tlase. Likopo Terata ea motlakase ea tšepe-chrome-aluminium e sebelisoa haholo bakeng sa ho etsa lintho tse futhumatsang tsa motlakase lisebelisoa tsa lapeng le liontong tsa indasteri. Mekhoa e tloaelehileng ea ts'ebeliso ke li-aene tse bataletseng, mechini ea ho aena, li-heater tsa metsi, li-dies tsa polasetiki tsa ho etsa li-molding, li-aene tsa ho soldera, likarolo tsa tšepe tse nang le sekoahelo sa tšepe le likarolo tsa cartridge. Sebaka sa kopo Lihlahisoa tsa rona li sebelisoa haholo lisebelisoa tsa kalafo ea mocheso, likarolo tsa likoloi, tlhahiso ea tšepe le tšepe, indasteri ea aluminium, lisebelisoa tsa tšepe, lisebelisoa tsa peterole, mechini ea khalase, mechini ea ceramic, mechini ea lijo, mechine ea meriana, le indasteri ea boenjiniere ba motlakase. Dikahare tsa Khemikhale, %

Litšobotsi tse ka sehloohong tsa tekheniki tsa FeCrAl Alloy:

| Lisebelisoa tsa motsoako | Sebopeho sa lik'hemik'hale % | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | ba bang | |

| boholo(≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | - | 3.5-4.5 | Phomolo | - |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | - | 4.5-5.3 | Phomolo | - |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | Phomolo | - |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | Phomolo | - |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | Phomolo | - |

| 0Cr19Al3 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 18.0-21.0 | ≤0.60 | 3.0-4.2 | Phomolo | - |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | Phomolo | Nb eketsa 0.5 |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.2 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | Phomolo | |

| LetšoaoThepa | 1Cr13Al4 | 1Cr21Al4 | 0Cr21Al6 | 0Cr23Al5 | 0Cr25Al5 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Karolo e kholo ea lik'hemik'hale% | Cr | 12.0-12.5 | 17.0-21.0 | 19.0-22.0 | 20.5-23.5 | 23.0-26.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 2.0-4.0 | 5.0-7.0 | 4.2-5.3 | 4.5-6.5 | 5.0-7.0 | 6.0-7.0 | |

| Fe | Tekanyo | Tekanyo | Tekanyo | Tekanyo | Tekanyo | Tekanyo | Tekanyo | |

| Re | Ho loketse | Ho loketse | Ho loketse | Ho loketse | Ho loketse | Ho loketse | Ho loketse | |

| Nomoro ea Tlatsetso: 0.5 | Ho eketsaKho: 1.8-2.2 | |||||||

| Mocheso o phahameng ka ho fetisisa oa tšebeliso ea karolo | 950 | 1100 | 1250 | 1250 | 1250 | 1350 | 1400 | |

| Sebaka sa ho Qhibiliha | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1510 | |

| Boima ba g/cm3 | 7.40 | 7.35 | 7.16 | 7.25 | 7.10 | 7.10 | 7.10 | |

| Ho hanyetsa μΩ·m,20 | 1.25±0.08 | 1.23±0.06 | 1.42±0.07 | 1.35±0.06 | 1.45±0.07 | 1.45±0.07 | 1.53±0.07 | |

| Matla a Tensile Mpa | 588-735 | 637-784 | 637-784 | 637-784 | 637-784 | 637-784 | 684-784 | |

| Sekhahla sa katoloso% | 16 | 12 | 12 | 12 | 12 | 10 | ||

| Maqhubu a kobehang a pheta-phetoang | 5 | 5 | 5 | 5 | 5 | |||

| Ho phahamisa ka potlako h/ | - | 80/1300 | 80/1300 | 50/1350 | ||||

| Mocheso o Ikhethang J/g. | 0.490 | 0.490 | 0.520 | 0.460 | 0.494 | 0.494 | 0.494 | |

| Coefficient ea ho Khanna Mocheso KJ/Mh | 52.7 | 46.9 | 63.2 | 60.1 | 46.1 | 46.1 | 45.2 | |

| Koefficient ea katoloso e otlolohileng aX10-6/(20-1000) | 15.4 | 13.5 | 14.7 | 15.0 | 16.0 | 16.0 | 16.0 | |

| Bothata HB | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Sebopeho se senyenyane | Ferritic | Ferritic | Ferritic | Ferritic | Ferritic | Ferritic | Ferritic | |

| Matla a khoheli | Matla a khoheli | Matla a khoheli | Matla a khoheli | Matla a khoheli | Matla a khoheli | Matla a khoheli | Matla a khoheli | |

Ngola molaetsa oa hau mona 'me u o romelle ho rona

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo