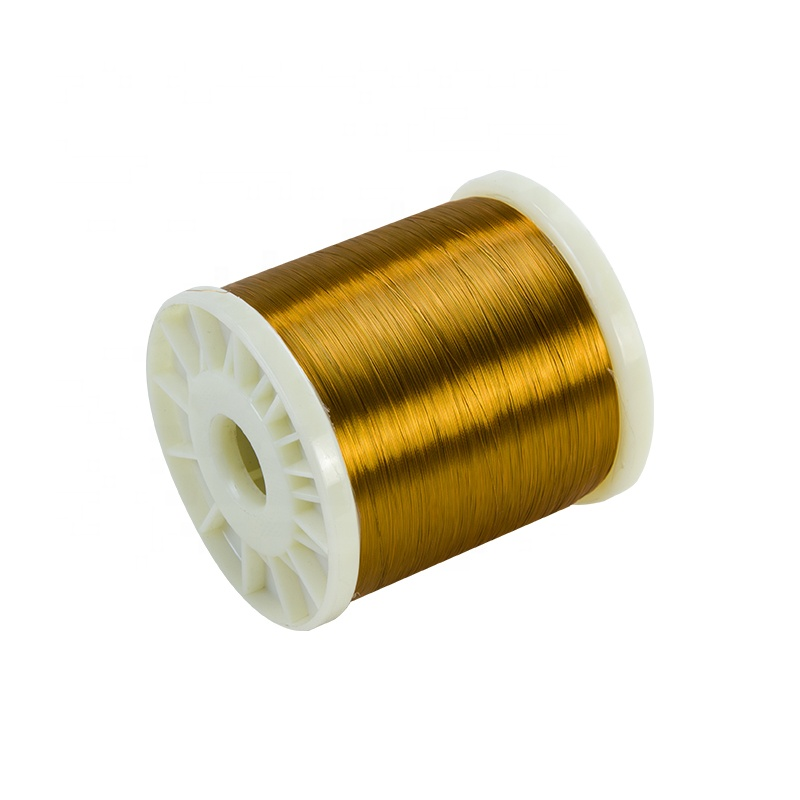

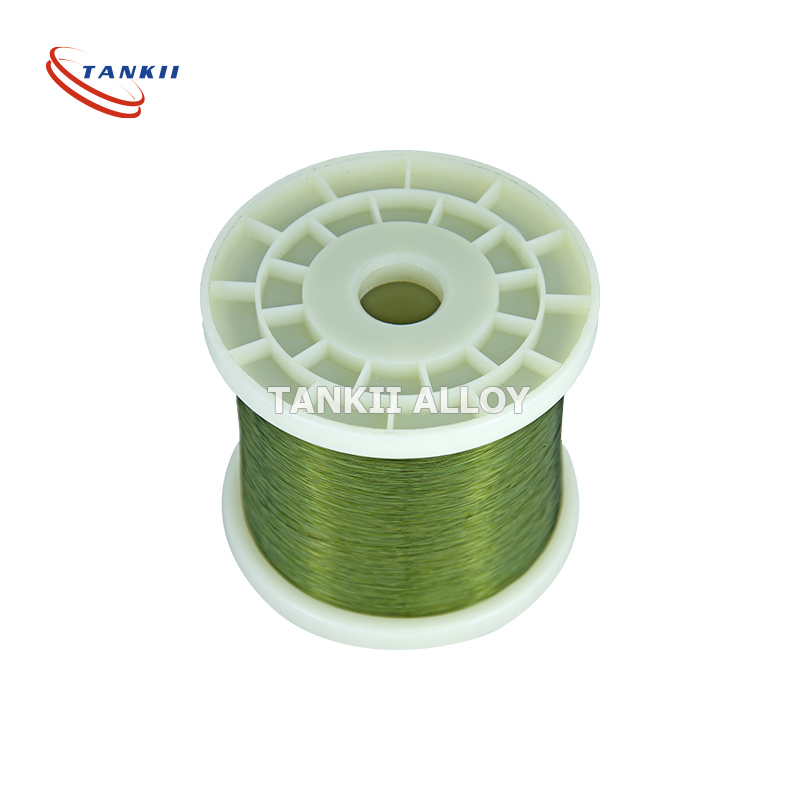

0.2mm 130 Sehlopha sa Enameled terata e mebala e chitja ea koporo e nang le motsoako oa Manganin

Terata e nang le enameled ea koporo ea sehlopha sa 130 Class Colored

1. Tlhaloso e Akaretsang ea Boitsebiso

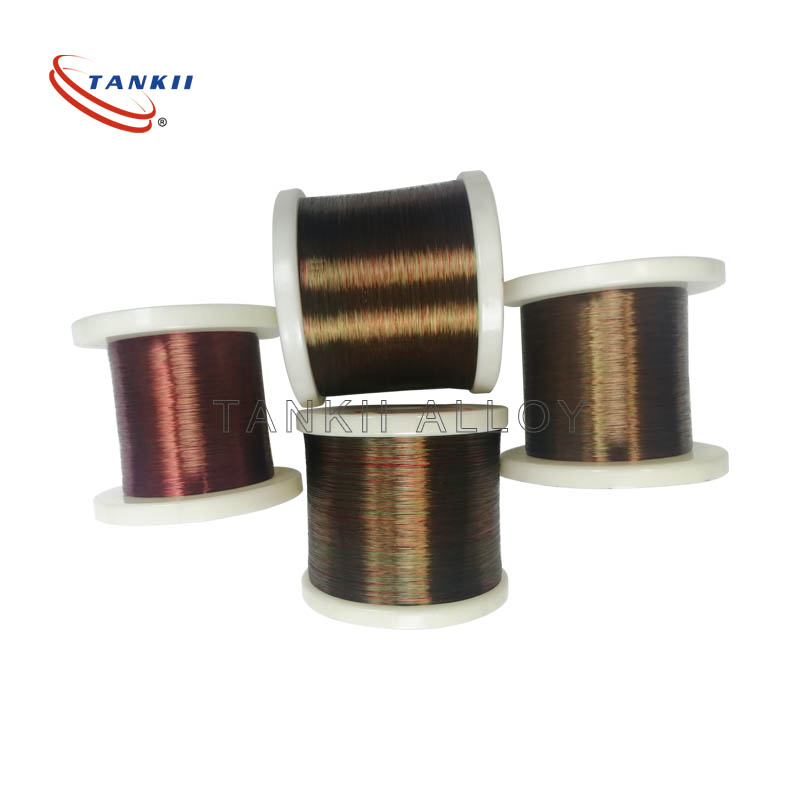

Motsoako oa koporo oa nickel, o nang le matla a tlase a ho hanyetsa motlakase, o hanela mocheso hantle ebile o hanela mafome, o bonolo ho sebetsoa le ho tjheseletsa ka loto. E sebelisoa ho etsa likarolo tsa bohlokoa ho relay ea overload ea mocheso, thermal resistance breaker ea potoloho, le lisebelisoa tsa motlakase. Hape ke thepa ea bohlokoa bakeng sa thapo ea ho futhumatsa ea motlakase. E tšoana le s type cupronickel. Ha nickel e le ngata, bokaholimo bo ba bosoeu ba silevera.

3. Sebopeho sa Lik'hemik'hale le Thepa e ka Sehloohong ea Motsoako oa Cu-Ni Low Resistance

| Sehlopha sa Matlo | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Sebopeho se Seholo sa Lik'hemik'hale | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bala | Bala | Bala | Bala | Bala | Bala | |

| Mocheso o Phahameng oa Tšebeletso o Tsoelang Pele (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Ho tiea ha matla ho 20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Botenya (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Motlakase oa Thermal (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Matla a ho Tenyetseha (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF khahlano le Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Sebaka se Hakanyetsoang sa ho Qhibiliha(oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Sebopeho sa Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Thepa ea Magnetic | eseng | eseng | eseng | eseng | eseng | eseng | |

| Sehlopha sa Matlo | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Sebopeho se Seholo sa Lik'hemik'hale | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bala | Bala | Bala | Bala | Bala | Bala | |

| Mocheso o Phahameng oa Tšebeletso o Tsoelang Pele (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Ho tiea ha matla ho 20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Botenya (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Motlakase oa Thermal (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Matla a ho Tenyetseha (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF khahlano le Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Sebaka se Hakanyetsoang sa ho Qhibiliha(oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Sebopeho sa Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Thepa ea Magnetic | eseng | eseng | eseng | eseng | eseng | eseng | |

2. Selelekela le lits'ebetso tsa terata e nang le enamel

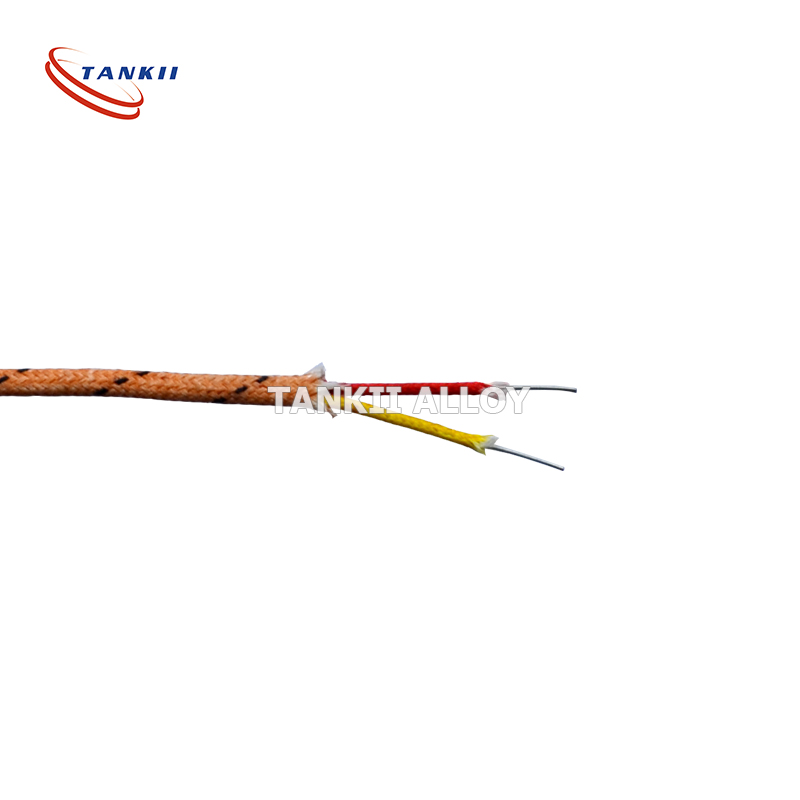

Leha e hlalosoa e le "e nang le enameled",terata e nang le enamelHa e le hantle, ha e apesoe ka lera la pente ea enamel kapa ka enamel ea vitreous e entsoeng ka phofo ea khalase e kopantsoeng. Terata ea sejoale-joale ea makenete hangata e sebelisa lera le le leng ho isa ho a mane (tabeng ea terata ea mofuta oa quad-film) ea insulation ea filimi ea polymer, hangata ea metsoako e 'meli e fapaneng, ho fana ka lera le thata, le tsoelang pele la insulation. Lifilimi tsa insulation tsa terata ea makenete li sebelisa (ka tatellano ea mocheso o ntseng o eketseha) polyvinyl formal (Formar), polyurethane, polyimide, polyamide, polyamide, polyster, polyester-polyimide, polyamide-polyimide (kapa amide-imide), le polyimide. Terata ea makenete e insulated ea polyimide e khona ho sebetsa ho fihlela ho 250 °C. Insulation ea terata ea makenete e teteaneng kapa e khutlonnetsepa hangata e eketsoa ka ho e phuthela ka polyimide ea mocheso o phahameng kapa teipi ea fiberglass, 'me li-winding tse phethiloeng hangata li tšeloa ka vacuum ka varnish e sireletsang ho ntlafatsa matla a insulation le ts'epo ea nako e telele ea winding.

Likhoele tse itšehetsang li tlameletsoe ka terata e koahetsoeng ka bonyane mekhahlelo e 'meli, e ka holimo e le thermoplastic e kopanyang likhutlo hammoho ha e futhumatsoa.

Mefuta e meng ea ho thibela mocheso e kang khoele ea fiberglass e nang le varnish, pampiri ea aramid, pampiri ea kraft, mica, le filimi ea polyester le eona e sebelisoa haholo lefatšeng ka bophara bakeng sa lits'ebetso tse fapaneng joalo ka li-transformer le li-reactor. Lefapheng la molumo, terata ea kaho ea silevera, le li-insulator tse ling tse fapaneng, joalo ka k'hothone (ka linako tse ling e nang le mofuta o itseng oa moemeli/setenya se kopanyang, joalo ka boka ba linotsi) le polytetrafluoroethylene (PTFE) li ka fumanoa. Lisebelisoa tsa khale tsa ho thibela mocheso li ne li kenyelletsa k'hothone, pampiri, kapa silika, empa tsena li na le thuso feela bakeng sa lits'ebetso tsa mocheso o tlase (ho fihlela ho 105°C).

Bakeng sa ho nolofatsa tlhahiso, terata e 'ngoe ea makenete ea boemo bo tlase e na le sethibela-mollo se ka tlosoang ke mocheso oa ho kopanya. Sena se bolela hore likhokahano tsa motlakase lipheletsong li ka etsoa ntle le ho tlosa sethibela-mollo pele.

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo