815 MPA lncoloy 925 UNS N09925 Motsoako oa ho tjhesa ha mafome

815 MPA lncoloy 925 UNS N09925 Sekoahelo sa moqolo oa mafome Tlhaloso:

Motsoako oa Incoloy 925 (UNS N09925) ka ho eketsoa ha molybdenum, koporo, titanium, le aluminium ke motsoako oa nickel-iron-chromium o thatafalang ka nako e telele, o fanang ka motsoako oa matla a phahameng le khanyetso e ntle ea mafome. Bongata ba nickel bo lekaneng bo fana ka tšireletso khahlanong le ho petsoha ha khatello ea chloride-ion ha e kopane le molybdenum le koporo tse ekelitsoeng, khanyetso ea lik'hemik'hale tse fokotsang ea natefeloa. Molybdenum e boetse e thusa ho hanyetsa mafome a sekoti le a ming, ha chromium e fana ka khanyetso ea tikoloho e oxidizing. Nakong ea kalafo ea mocheso, karabelo e matlafatsang e bakoa ke ho eketsoa ha titanium le aluminium.

Ditshebediso tse hlokang motswako wa matla a hodimo le ho hanyetsa mafome di ka nahana ka alloy alloy 925. Ho hanyetsa kgatello ya sulfide le ho phatloha ha kgatello le mafome dibakeng tsa oli e tala e "bolila" le kgase ya tlhaho ho bolela hore e sebedisetswa dikarolo tsa khase tse ka tlase le tse ka hodima metsi hammoho le ho fumana tshebediso di-marine shafts le pompong kapa ditsamaisong tsa diphaephe tse matla haholo.

-

1. Tlhokahalo ea Sebopeho sa Lik'hemik'hale

Sebopeho sa Lik'hemik'hale sa Incoloy 925 Nikele 42.0-46.0 Chromium 19.5-22.5 Tšepe ≥22.0 Molybdenum 2.5-3.5 Koporo 1.5-3.0 Titanium 1.9-2.4 Alumium 0.1-0.5 Manganese ≤1.00 Silicone ≤0.50 Niobium ≤0.50 Khabone ≤0.03 Sebabole ≤0.30

-

2. Thepa ea Mekaniki ea Incoloy 925

Matla a ho Tenyetseha, bonyane. Matla a Tekanyo, bonyane. Ho lelefatsa, bonyane. Boima, bonyane. Mpa ksi Mpa ksi % HRC 1210 176 815 118 24 36.5 3. Thepa ea 'Mele ea Incoloy 925

Botenya Sebaka sa ho Qhibiliha Mocheso o Ikhethang Ho hanyetsa motlakase g/cm3 °F °C J/kg.k Btu/lb. °F µΩ·m 8.08 2392-2490 1311-1366 435 0.104 1166 4. Mefuta le Maemo a Sehlahisoa

Foromo ea Sehlahisoa E tloaelehileng Thupa, bareng le terata ASTM B805 Poleiti, lakane lehlobolisa ASTM B872 Phaephe le tube tse se nang seamless ASTM B983 Ho betla ASTM B637

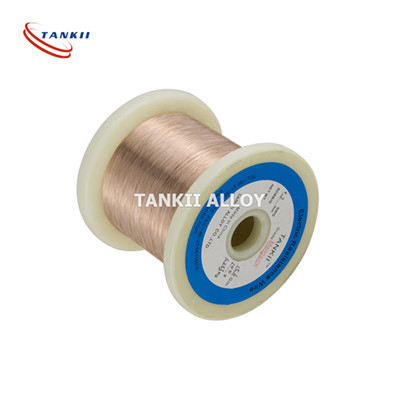

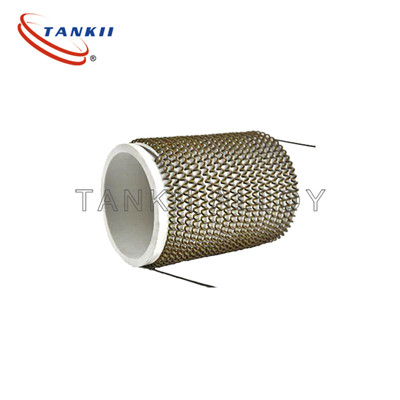

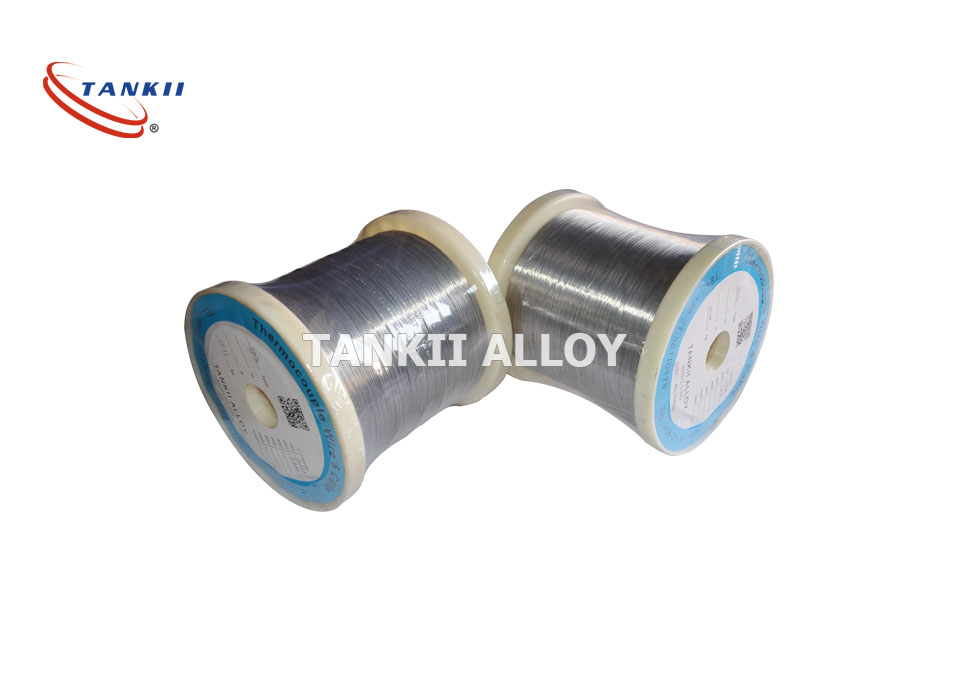

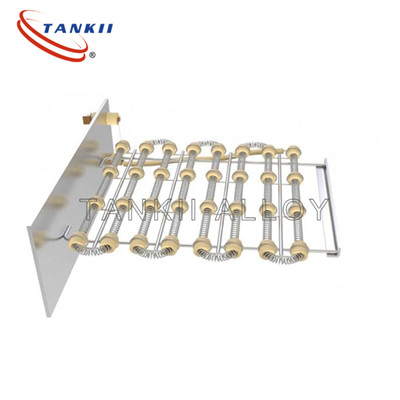

Litšoantšo tsa lintlha tsa sehlahisoa:

Tataiso ea Sehlahisoa se Amanang:

Re thabela boemo bo botle haholo har'a bareki ba rona ba ka bang le boleng bo holimo ba thepa ea rona e kholo, theko e hlōlisanang le tšebeletso e loketseng 815 MPA lncoloy 925 UNS N09925 Corrosion strip Alloy, Sehlahisoa sena se tla fanoa lefatšeng ka bophara, joalo ka: Philadelphia, Nicaragua, Yemen, Ho fihlela melemo ea ho arolelana, k'hamphani ea rona e matlafatsa maqiti a rona a lefats'e ka bophara mabapi le puisano le bareki ba mose ho maoatle, phano e potlakileng, boleng bo holimo le tšebelisano-'moho ea nako e telele. Khamphani ea rona e tšehetsa moea oa "boqapi, kutloano, mosebetsi oa sehlopha le ho arolelana, litsela, tsoelo-pele e sebetsang". Re fe monyetla 'me re tla paka bokhoni ba rona. Ka thuso ea hau e mosa, re lumela hore re ka theha bokamoso bo khanyang le uena hammoho.

Ha ho bonolo ho fumana mofani ea nang le boiphihlelo le ea ikarabellang joalo mehleng ena. Re tšepa hore re ka boloka tšebelisano-'moho ea nako e telele.

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo