Terata e khanyang ea motsoako oa NiCr8020/N8 bakeng sa Sealer

E khanyangNiCr8020/N8Terata ea motsoako bakeng sa Sealer

Ni80Cr20ke motsoako oa nickel-chromium (motsoako oa NiCr) o khetholloang ka ho hanyetsa ho phahameng, ho hanyetsa hantle ha oxidation le botsitso bo botle haholo ba sebopeho. E loketse ho sebelisoa mochesong o fihlang ho 1200°C, 'me e na le bophelo bo botle ba ts'ebeletso ha e bapisoa le metsoako ea tšepe ea chromium alumium.

Ditshebediso tse tlwaelehileng bakeng sa Ni80Cr20 ke dielemente tsa ho futhumatsa tsa motlakase disebedisweng tsa lapeng, dionto tsa diindasteri le di-resistor (di-resistor tsa maqeba a terata, di-resistor tsa filimi ya tshepe), di-aene tse bataletseng, metjhini ya ho aena, di-heater tsa metsi, di-dies tsa polasetiki tsa ho bopa, di-aene tsa ho solder, dielemente tsa tubular tse nang le sheath ya tshepe le dielemente tsa cartridge.

Sebopeho se tloaelehileng%

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Tse ling |

| Boholo | |||||||||

| 0.03 | 0.02 | 0.015 | 0.60 | 0.75~1.60 | 20.0~23.0 | Bala. | Boholo 0.50 | Boholo 1.0 | - |

Thepa e tloaelehileng ea Mechanical (1.0mm)

| Matla a tlhahiso | Matla a tšepe | Ho lelefatsa |

| Mpa | Mpa | % |

| 420 | 810 | 30 |

Litšobotsi tse tloaelehileng tsa 'mele

| Botenya (g/cm3) | 8.4 |

| Ho hanyetsa motlakase ho 20ºC(mm2/m) | 1.09 |

| Koefficient ea ho tsamaisa motlakase ho 20ºC (WmK) | 15 |

| Tekanyo e sebetsang ea katoloso ea mocheso | |

| Thempereichara | Katoloso ea Thermal Coefficient x10-6/ºC |

| 20 ºC- 1000ºC | 18 |

| Bokhoni bo itseng ba mocheso | |

| Thempereichara | 20ºC |

| J/gK | 0.46 |

| Sebaka sa ho qhibiliha (ºC) | 1400 |

| Mocheso o phahameng o sebetsang o tsoelang pele moeeng (ºC) | 1200 |

| Matlotlo a makenete | e seng ea makenete |

| Lintlha tsa Thempereichara tsa ho Hlōla Motlakase | |||||

| 20ºC | 100ºC | 200ºC | 300ºC | 400ºC | 600ºC |

| 1 | 1.006 | 1.012 | 1.018 | 1.025 | 1.018 |

| 700ºC | 800ºC | 900ºC | 1000ºC | 1100ºC | 1300ºC |

| 1.01 | 1.008 | 1.01 | 1.014 | 1.021 | - |

Mokhoa oa phepelo

| Lebitso la Li-alloy | Mofuta | Tekanyo | ||

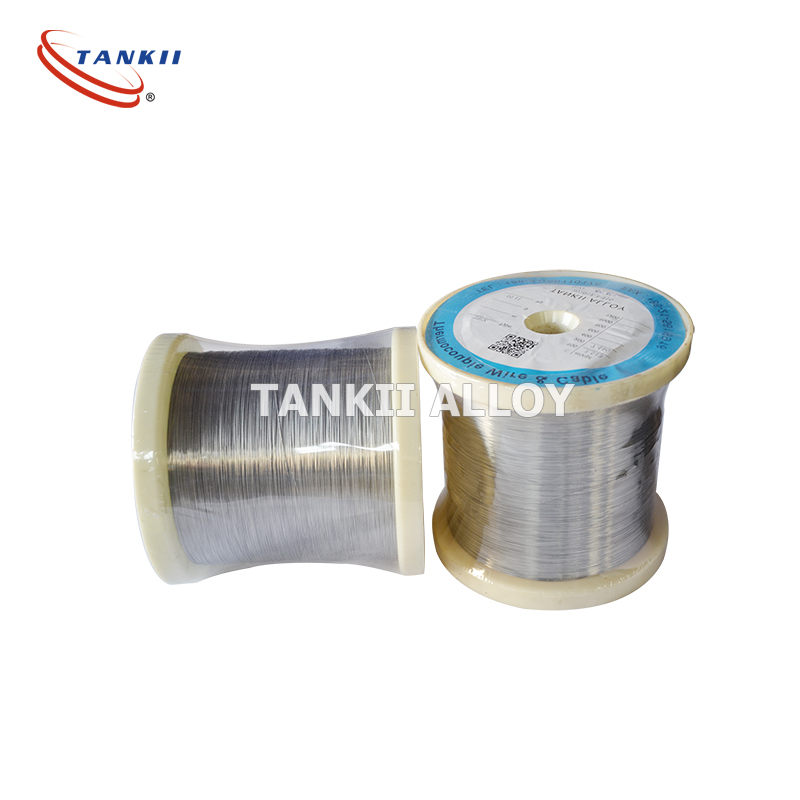

| Ni80Cr20W | Terata | D=0.03mm~8mm | ||

| Ni80Cr20R | Ribone | W=0.4~40 | T=0.03~2.9mm | |

| Ni80Cr20S | Sekoahelo | W=8~250mm | T=0.1~3.0 | |

| Ni80Cr20F | Foile | W=6~120mm | T=0.003~0.1 | |

| Ni80Cr20B | Bare | Bophara = 8 ~ 100mm | L=50~1000 | |

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo