Rea u amohela liwebsaeteng tsa rona!

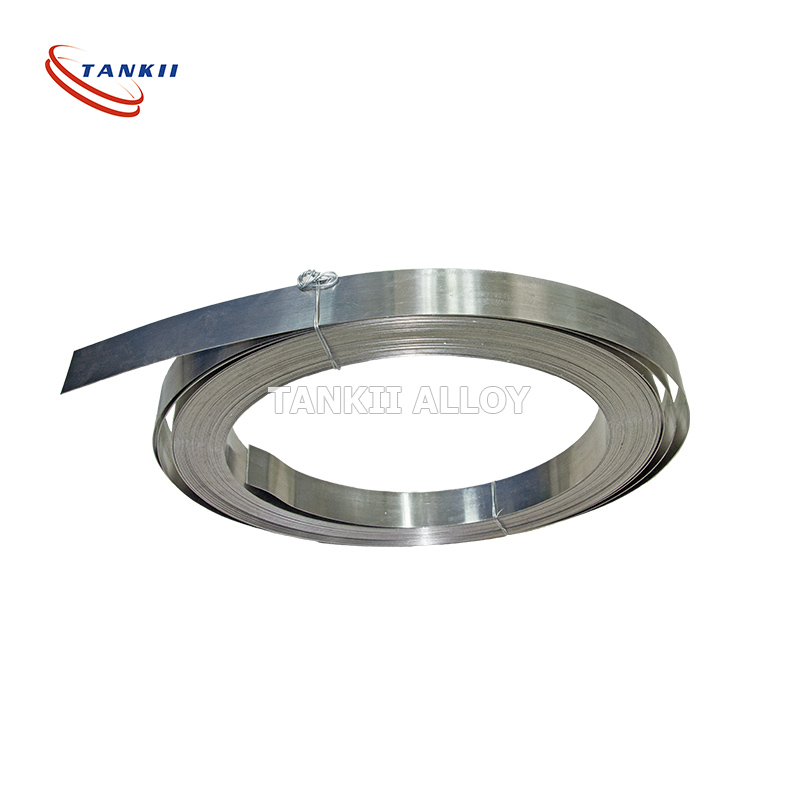

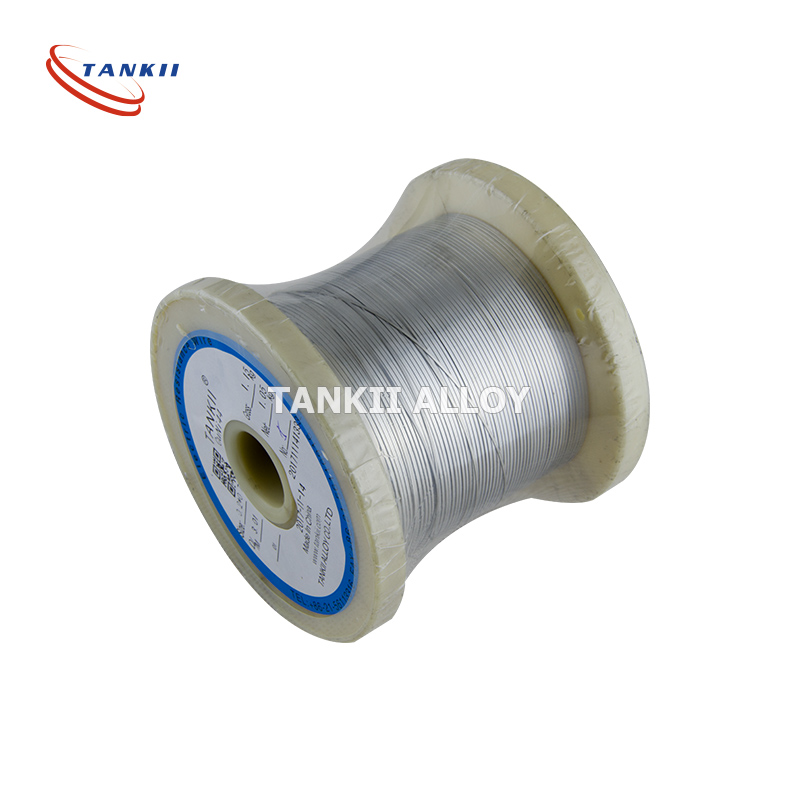

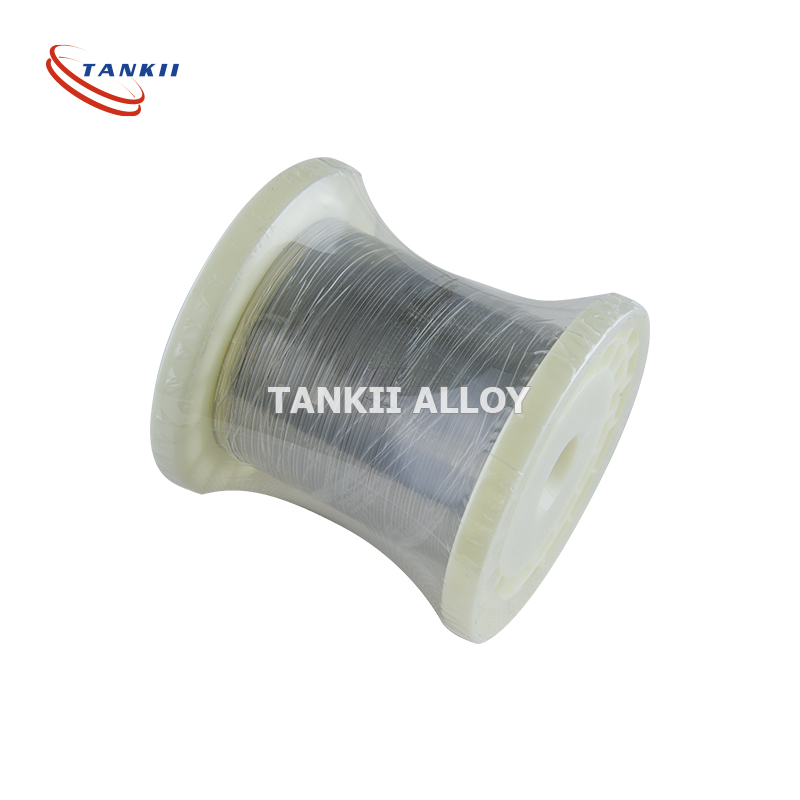

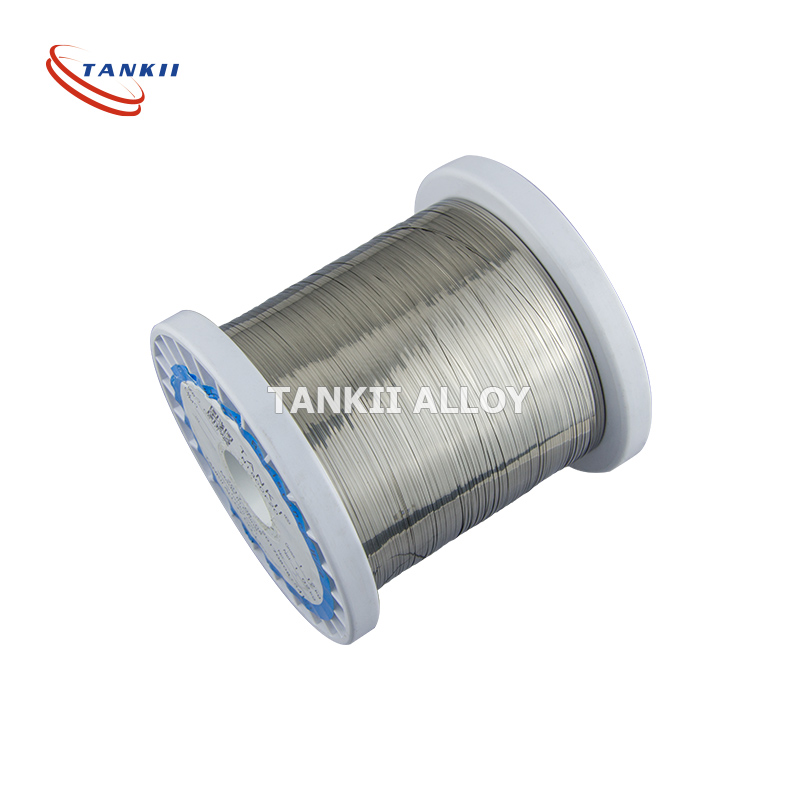

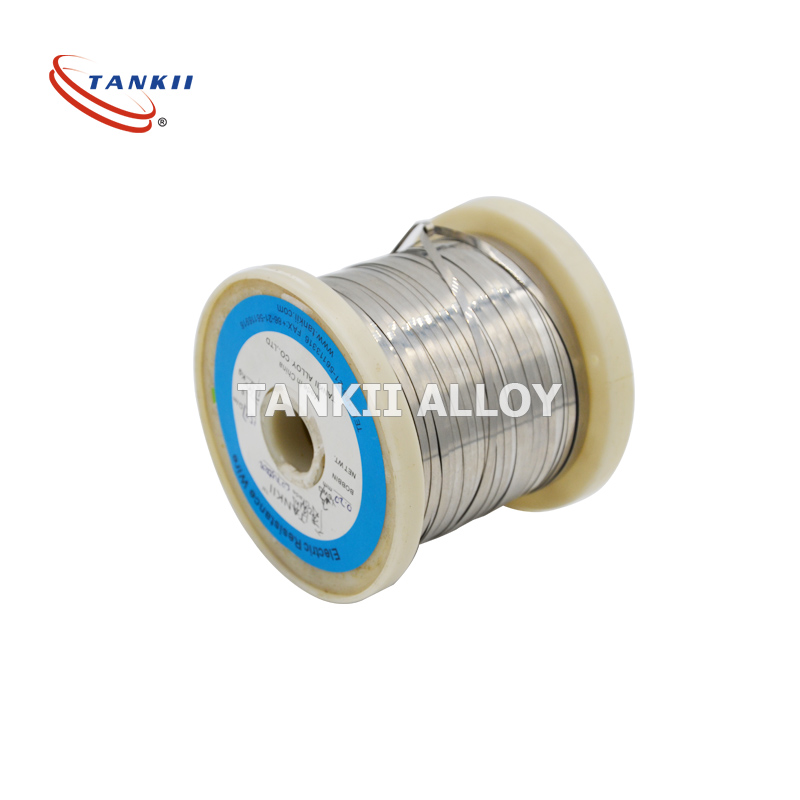

Constantan Flat Wire Copper Nickel Alloy 6j40 Ribone 0.4*2mm

Lebenkele le Lecha la Constantan Flat Wire Copper Nickel Alloy 6j11 Ribone 0.4*2mm

| Tšobotsi | Ho hanyetsa (200C μΩ.m) | Mocheso o sebetsang ka ho fetisisa (0C) | Matla a ho Tenyetseha (Mpa) | Sebaka sa ho qhibiliha (0C) | Botenya (g/cm3) | TCR x10-6/ 0C (20~600 0C) | EMF vs Cu (μ V/ 0C) (0~100 0C) |

| Lebitso la Motsoako | |||||||

| NC003 (CuNi1) | 0.1 | 200 | ≥ 250 | 1095 | 8.9 | < 100 | -12 |

![]()

![]()

![]()

![]()

| Matlotlo a 'Mele | Metric | Maikutlo |

| Botenya | 8.94 g/cc | |

| Matlotlo a Mekaniki | Metric | Maikutlo |

| Matla a ho Thabisa, a Bohlokoa ka ho Fetisisa | 262 – 531 MPa | |

| Matla a ho Thabisa, Tekanyo | 276 – 524 MPa | Ho itšetlehile ka bohale |

| Ho Lelefatsa Nako ea Phomolo | 46.0% | ka 50.8 mm. |

| Modulus ea Elasticity | 115 GPa | |

| Karolelano ea Poissons | 0.310 | E baliloe |

| Ho sebetsa ha mechine | 20% | UNS C36000 (koporo e sehang ka bolokolohi) = 100% |

| Modulus ea Shear | 44.0 GPa | |

| Matlo a Motlakase | Metric | Maikutlo |

| Ho hanyetsa motlakase | 0.0000120 ohm-cm @Thempereichara 20.0 ° C | |

| Matlotlo a Thermal | Metric | Maikutlo |

| CTE, e otlolohileng | 17.5 µ m/m-° C @Thempereichara 20.0 – 300 ° C | |

| Bokhoni bo Ikhethang ba Mocheso | 0.380 J/g-° C | |

| Ho khanna ha mocheso | 64.0 W/mK @Thempereichara 20.0 ° C | |

| Sebaka sa ho Qhibiliha | < = 1125 ° C | Liquidus |

| Liquidus | 1125 ° C | |

| Matlotlo a Ts'ebetso | Metric | Maikutlo |

| Mocheso oa Annealing | 565 – 815 ° C | |

| Mocheso o Sebetsang ka Mocheso | 815 – 950 ° C | |

| Matlotlo a Likarolo tsa Likarolo | Metric | Maikutlo |

| Koporo, Cu | > = 91.2% | |

| Tšepe, Fe | 1.30 – 1.70% | |

| Moetapele, Pb | < = 0.050 % | |

| Manganese, Mn | 0.30 – 0.80% | |

| Nikele, Ni | 4.80 – 6.20% | |

| Zinki, Zn | < = 1.0% |

![]()

![]()

![]()

![]()

Dikahare tsa Khemikhale tsa CuNi44, %

| Ni | Mn | Fe | Si | Cu | Tse ling | Tataiso ea ROHS | |||

| Cd | Pb | Hg | Cr | ||||||

| 44 | 1% | 0.5 | - | Bala | - | ND | ND | ND | ND |

![]()

![]()

![]()

![]()

Matlotlo a Mekaniki

| Tempera e Phahameng ea Tšebeletso e Tsoelang Pele | 400ºC |

| Ho tsitsa ha mocheso ho 20ºC | 0.49±5%ohm mm2/m |

| Botenya | 8.9 g/cm3 |

| Ho khanna ha mocheso | -6(Boholo) |

| Sebaka sa ho Qhibiliha | 1280ºC |

| Matla a ho Tenyetseha, N/mm2 e tšehelitsoeng, e bonolo | 340~535 Mpa |

| Matla a ho Tenyetseha, N/mm3 e Menoang ka Serame | 680~1070 Mpa |

| Ho lelefatsa (ho eketsa) | 25% (Bonyane) |

| Ho lelefatsa (ho phutholohile ka serame) | ≥Bonyane)2% (Bonyane) |

| EMF khahlanong le Cu, μV/ºC (0~100ºC) | -43 |

| Sebopeho sa Micrographic | austenite |

| Thepa ea Magnetic | Hase |

![]()

![]()

![]()

![]()

Ngola molaetsa oa hau mona 'me u o romelle ho rona

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo