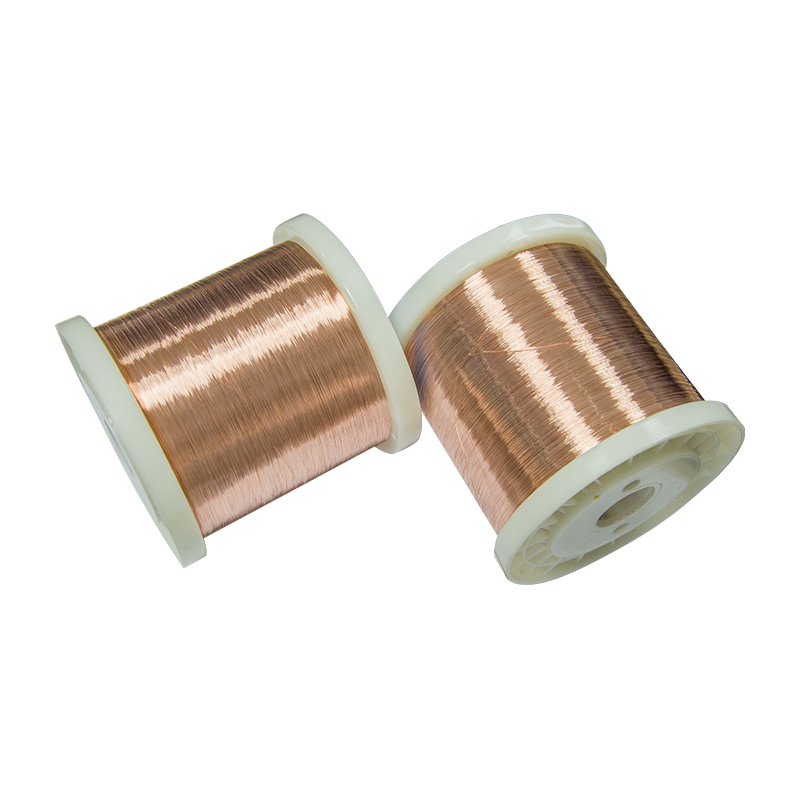

Lithapo tsa Beryllium tsa Dia 0.6mm Alloy M25 Copper Beryllium bakeng sa Marokho a ho Kopana

Tlhaloso ea Sehlahisoa

Sebopeho sa Lik'hemik'hale (Peresente ea Boima) eaMotsoako oa Koporo oa C17200 Beryllium:

| Ho Fana ka Litharollo | ||||||

| Motsoako | Beryllium | Cobalt | Nikele | Co + Ni | Co+Ni+Fe | Koporo |

| C17200 | 1.80-2.00 | - | Metsotso e 0.20 | Metsotso e 0.20 | 0.60 Max | Tekanyo |

Tlhokomeliso: Koporo hammoho le litlatsetso li lekana le 99.5% Min.

TLitšobotsi tsa 'Mele tsa C172:

Botenya (g/cm3): 8.36

Botenya pele bo tsofala (g/cm3): 8.25

Modulus e tenyetsehang (kg/mm2 (103)): 13.40

Koefficient ea Katoloso ea Thermal (20 °C ho isa ho 200 °C m/m/°C): 17 x 10-6

Ho tsamaisa mocheso (cal/(cm-s-°C)): 0.25

Sebaka sa ho Qhibiliha (°C): 870-980

Tempere e Tloaelehileng eo re fanang ka eona:

| Tlhophiso ea CuBeryllium | ASTM | Thepa ea Mekaniki le ea Motlakase ea Koporo ea Beryllium Strip | ||||||

| Tlhophiso | Tlhaloso | Matla a tšepe (Mpa) | Matla a Tlhahiso a 0.2% a fokotsoa | Peresente ea ho Lelefatsa | BOTHATA (HV) | BOTHATA Rockwell Sekala sa B kapa C | Ho Tsamaisa Motlakase (% IACS) | |

| A | TB00 | Tharollo e Annealed | 410~530 | 190~380 | 35~60 | <130 | 45~78HRB | 15~19 |

| 1/2 H | TD02 | Halofo e thata | 580~690 | 510~660 | 12~30 | 180~220 | 88~96HRB | 15~19 |

| H | TD04 | Ka thata | 680~830 | 620~800 | 2~18 | 220~240 | 96~102HRB | 15~19 |

| HM | TM04 | Tshilo e thatafalitsoe | 930~1040 | 750~940 | 9~20 | 270~325 | 28~35HRC | 17~28 |

| SHM | TM05 | 1030~1110 | 860~970 | 9~18 | 295~350 | 31~37HRC | 17~28 | |

| XHM | TM06 | 1060~1210 | 930~1180 | 4~15 | 300~360 | 32~38HRC | 17~28 | |

Theknoloji ea Bohlokoa ea Koporo ea Beryllium (Kalafo ea mocheso)

Kalafo ea mocheso ke ts'ebetso ea bohlokoa ka ho fetisisa bakeng sa sistimi ena ea alloy. Le hoja li-alloy tsohle tsa koporo li thatafala ka ho sebetsa ka serame, koporo ea beryllium e ikhetha ka ho thatafala ka kalafo e bonolo ea mocheso o tlase. E kenyelletsa mehato e 'meli ea motheo. Ea pele e bitsoa ho hlohlelletsa tharollo 'me ea bobeli, ho nosetsa kapa ho thatafatsa botsofali.

Tharollo ea ho Hloekisa

Bakeng sa motsoako o tloaelehileng oa CuBe1.9 (1.8- 2%) motsoako o futhumatsoa pakeng tsa 720°C le 860°C. Nakong ena beryllium e nang le eona ha e le hantle e "qhibilihisoa" ka har'a matrix ea koporo (mokhahlelo oa alpha). Ka ho tima ka potlako mochesong oa kamore, sebopeho sena se tiileng sa tharollo sea bolokoa. Thepa mohatong ona e bonolo haholo ebile e teteane 'me e ka bata habonolo ka ho hula, ho etsa ho phutholoha, kapa ho tšoara ka serame. Ts'ebetso ea ho kenya tharollo ke karolo ea ts'ebetso ho sile 'me hangata ha e sebelisoe ke moreki. Mocheso, nako mochesong, sekhahla sa ho tima, boholo ba lijo-thollo le boima kaofela ke liparamente tsa bohlokoa haholo 'me li laoloa ka thata ke TANKII.

Ho thatafatsa Botsofali

Ho thatafatsa botsofali ho eketsa matla a thepa haholo. Karabelo ena hangata e etsoa mochesong o pakeng tsa 260°C le 540°C ho latela motsoako le litšobotsi tse lakatsehang. Potoloho ena e etsa hore beryllium e qhibilihisitsoeng e potlake e le mohato o ruileng oa beryllium (gamma) matrix le meeling ea lithollo. Ke ho thehoa ha potlaka hona ho bakang keketseho e kholo ea matla a thepa. Boemo ba thepa ea mechini bo fihletsoeng bo khethoa ke mocheso le nako mochesong. Ho lokela ho hlokomeloa hore koporo ea beryllium ha e na litšobotsi tsa botsofali ba mocheso oa kamore.

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo