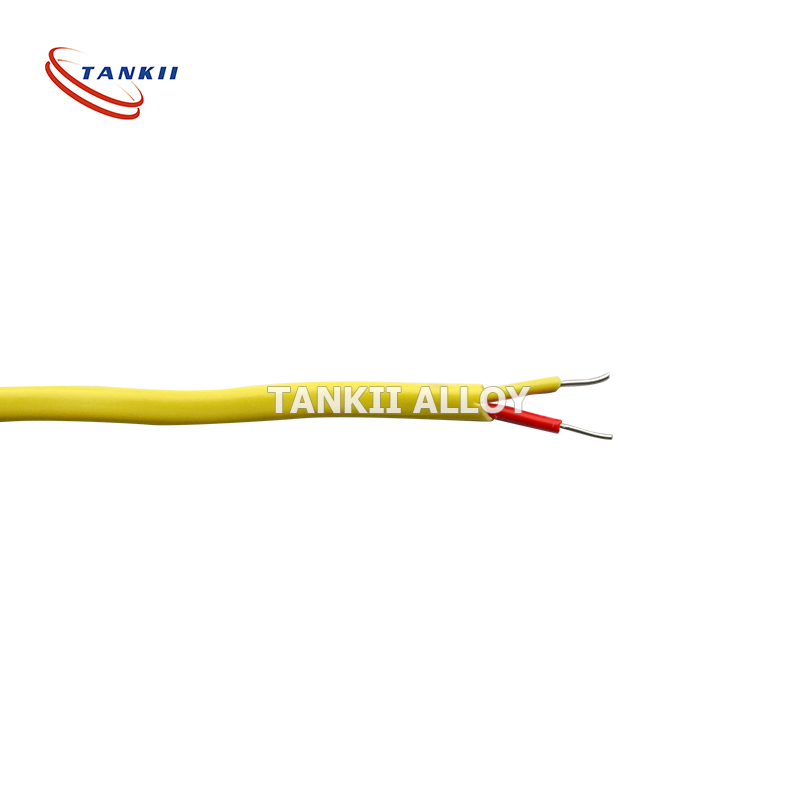

Sesebelisoa sa ho Sireletsa sa PTFE se Tšoarellang N Thermocouple Alloy

Litlhaloso

1.Mokhoa:Terata ea Katoloso

2.Thermocoupleterata ea koporo

Sehlopha sa terata ea koporo ea thermocouple

1. Boemo ba thermocouple (boemo ba mocheso o phahameng). Mofuta ona wa terata ya thermocouple o loketse haholo mofuta wa thermocouple K, J, E, T, N le L le sesebediswa se seng sa ho lemoha mocheso o phahameng, sensor ya mocheso, jj.

2. Terata e lefellang boemo (boemo bo tlase ba mocheso). Mofuta ona wa terata ya thermocouple o loketse haholo bakeng sa ho lefella thapo le terata ya katoloso ya di-thermocouple tse fapaneng tsa mofuta wa S, R, B, K, E, J, T, N le L, thapo ya ho futhumatsa, thapo ya taolo le tse ding.

Mefuta le li-index tsa thermocouple

| Mefuta-futa ea Thermocouple le Index | ||

| Mefuta e fapaneng | Mofuta | Sebaka sa Tekanyo(°C) |

| NiCr-NiSi | K | -200-1300 |

| NiCr-CuNi | E | -200-900 |

| Fe-CuNi | J | -40-750 |

| Cu-CuNi | T | -200-350 |

| NiCrSi-NiSi | N | -200-1300 |

| NiCr-AuFe0.07 | NiCr-AuFe0.07 | -270-0 |

Litekanyo le Mamello ea Terata ea Thermocouple e Insulated ea Fiberglass

Litekanyo / Mamello mm): 4.0+-0.25

Khoutu ea 'mala le mamello ea tlhahlobo ea pele bakeng sa terata ea thermocouple:

| Mofuta oa Thermocouple | Khoutu ea 'Mala ea ANSI | Mamello ea pele ea ho lekanya | ||||

| Litšepe tse kopantsoeng tsa terata | Tekanyo | +/- Motsamaisi | Jekete | Boemo ba Thempereichara | E tloaelehileng Meeli | E khethehileng Meeli |

| Tšepe(+) khahlanong le Constantan(-) | J | Bosweu/Bofubelu | Sootho | 0°C ho isa ho +285°C 285°C ho isa ho +750°C | ±2.2°C ± .75% | ±1.1°C ± .4% |

| CHROMEL(+) khahlano le ALUMEL(-) | K | Bosehla/Bofubelu | Sootho | -200°C ho isa ho -110°C -110°C ho isa ho 0°C 0°C ho isa ho +285°C 285°C ho isa ho +1250°C | ± 2% ±2.2°C ±2.2°C ± .75% | ±1.1°C ± .4% |

| Koporo(+) khahlanong le Constantan(-) | T | Putsoa/Bofubelu | Sootho | -200°C ho isa ho -65°C -65°C ho isa ho +130°C 130°C ho isa ho +350°C | ± 1.5% ±1°C ± .75% | ± .8% ± .5°C ± .4% |

| CHROMEL(+) khahlano le Constantan(-) | E | Pherese/Bofubelu | Sootho | -200°C ho isa ho -170°C -170°C ho isa ho +250°C 250°C ho isa ho +340°C 340°C+900°C | ± 1% ±1.7°C ±1.7°C ± .5% | ±1°C ±1°C ± .4% ± .4% |

Khoutu ea 'Mala le Mamello ea ho Lekanya ea Pele bakeng sa Terata ea Katoloso:

| Mofuta oa katoloso | Khoutu ea 'Mala ea ANSI | Mamello ea pele ea ho lekanya | ||||

| Litšepe tse kopantsoeng tsa terata | Tekanyo | +/- Motsamaisi | Jekete | Boemo ba Thempereichara | E tloaelehileng Meeli | E khethehileng Meeli |

| Tšepe (+) khahlanong le Constantan(-) | JX | Bosweu/Bofubelu | Botsho | 0°C ho isa ho +200°C | ±2.2°C | ±1.1°C |

| CHROMEL (+) khahlano le ALUMEL (-) | KX | Bosehla/Bofubelu | Bosehla | 0°C ho isa ho +200°C | ±2.2°C | ±1.1°C |

| Koporo(+) khahlanong le Constantan(-) | TX | Putsoa/Bofubelu | Putsoa | -60°C ho isa ho +100°C | ±1.1°C | ± .5°C |

| CHROMEL(+) khahlano le Constantan(-) | EX | Pherese/Bofubelu | Pherese | 0°C ho isa ho +200°C | ±1.7°C | ±1.1°C |

Litšobotsi tsa 'Mele tsa PVC-PVC:

| Litšobotsi | Ho kenya mocheso | Jekete |

| Khanyetso ea Abrasion | Ho lokile | Ho lokile |

| Khaola Khahlanong le Khanyetso | Ho lokile | Ho lokile |

| Khanyetso ea mongobo | E babatsehang | E babatsehang |

| Khanyetso ea Tšepe ea Solder | Mafutsana | Mafutsana |

| Mocheso oa Tšebeletso | 105ºC e tsoelang pele 150ºC e le 'ngoe | 105ºC e tsoelang pele 150ºC e le 'ngoe |

| Teko ea Mollo | Ho itima | Ho itima |

Boemo ba Khoebo

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo