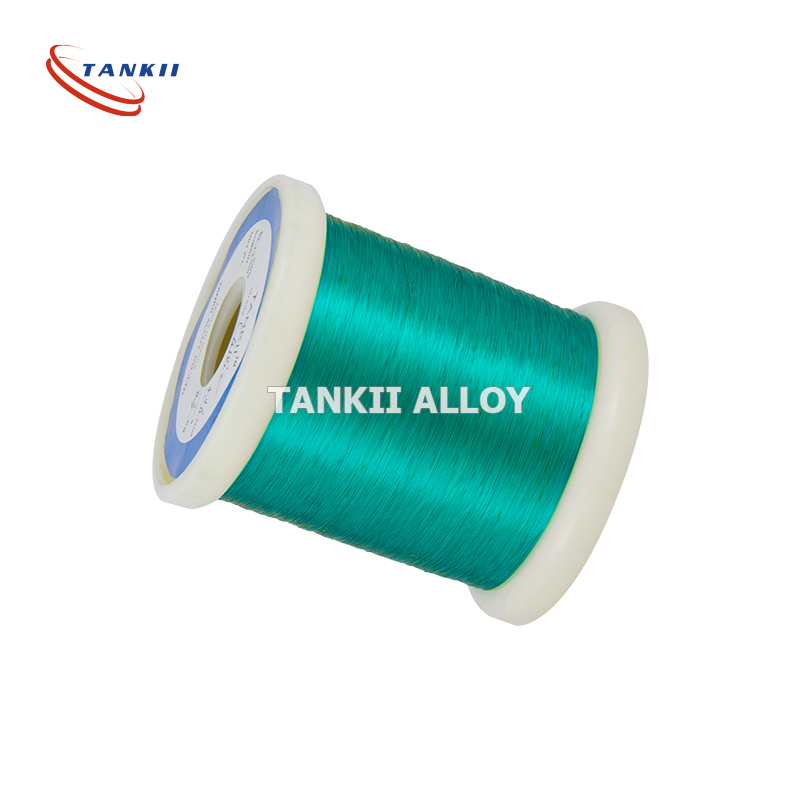

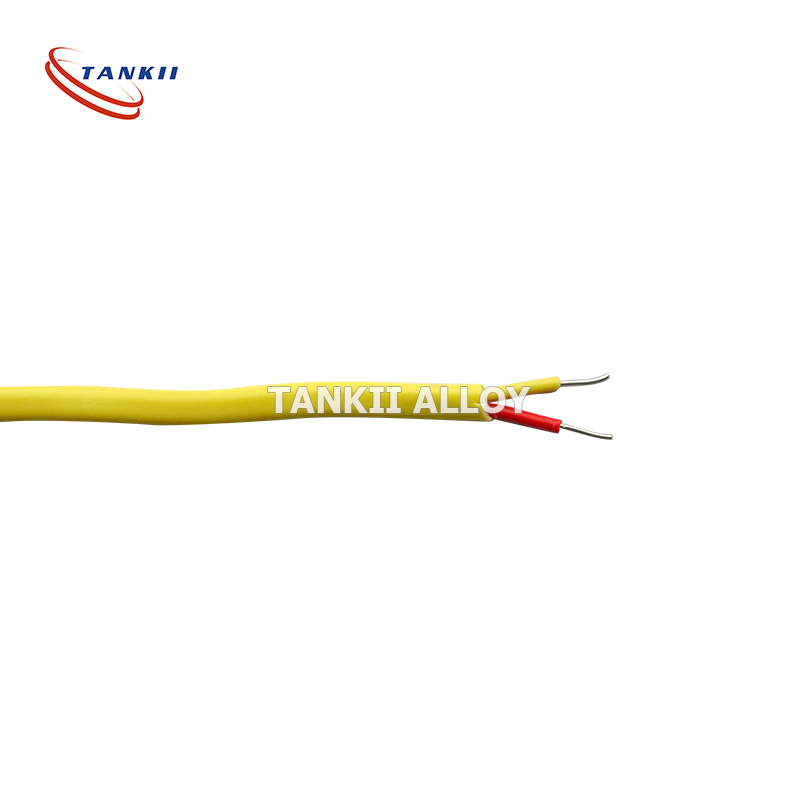

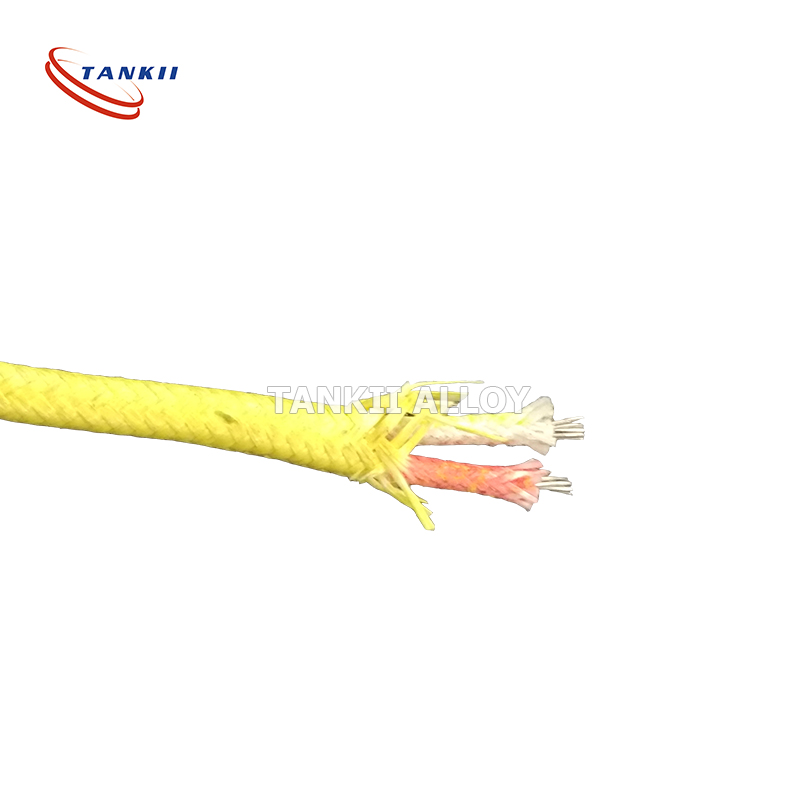

Enameled Nichrome /Constantan /Copper / Lizt / Mohala oa 'Mala / Mohala oa Silevera / Twist

Tlhaloso ea Sehlahisoa

Lithapo tsena tse hanyetsanang tse nang le enamel li sebelisitsoe ka bophara bakeng sa li-resistor tse tloaelehileng, likoloi

likarolo, li-resistors tse kobehang, jj. ho sebelisoa ts'ebetso ea ho kenya mocheso e loketseng lits'ebetso tsena, ho sebelisa ka botlalo likarolo tse ikhethang tsa ho roala ka enamel.

Ho feta moo, re tla etsa ho thibela ho kwahela ka enamel ka terata ya tshepe ya bohlokwa jwalo ka silefera le terata ya platinum ha o odara. Ka kopo sebedisa tlhahiso ena ha o odara.

Mofuta oa Terata ea Nichrome

NiCr80/20,NiCr70/30,NiCr60/15,NiCr90/10,NiCr35/20,NiCr30/20

Mofuta oa ho kenya mocheso

| Lebitso le nang le enamel ea insulation | Boemo ba ThermalºC (Nako ea ho sebetsa ke 2000h) | Lebitso la Khoutu | Khoutu ea GB | Mofuta oa ANSI |

| Terata e entsoeng ka enamel ea polyurethane | 130 | UEW | QA | MW75C |

| Terata e entsoeng ka enamel ea polyester | 155 | PEW | QZ | MW5C |

| Terata e entsoeng ka enamel ea polyester-imide | 180 | EIW | QZY | MW30C |

| Polyester-imide le polyamide-imide tse koahetsoeng habeliterata e nang le enamel | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Terata e entsoeng ka enamel ea polyamide-imide | 220 | AIW | QXY | MW81C |

Mofuta oa terata ea motsoako o se nang letho

Motsoako oo re ka o etsang ka enamelled ke terata ea koporo-nickel alloy, terata ea Constantan, terata ea Manganin. Kama Wire, terata ea NiCr Alloy, terata ea FeCrAl Alloy jj.

| sehlooho thepa mofuta | Cuni1 | CuNI2 | CuNI6 | CuNi8 | CuNI10 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNI44 | |

| sehlooho lik'hemik'hale sebopeho | Ni | 1 | 2 | 6 | 8 | 10 | 19 | 23 | 30 | 34 | 44 |

| MN | / | / | / | / | / | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| CU | phomolo | phomolo | phomolo | phomolo | phomolo | phomolo | phomolo | phomolo | phomolo | phomolo | |

| boholo ho sebetsa mocheso | / | 200 | 220 | 250 | 250 | 300 | 300 | 350 | 350 | 400 | |

| bongata g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| ho hanyetsa ho 20 °c | 0.03 ± 10% | 0.05± 10% | 0.10± 10% | 0.12± 10% | 0.15± 10% | 0.25± 5% | 0.30± 5% | 0.35± 5% | 0.40± 5% | 0.49± 5% | |

| mocheso karolelano ea khanyetso | <100 | <120 | <60 | <57 | <50 | <25 | <16 | <10 | -0 | <-6 | |

| ho tsitlella matla a mpa | >210 | >220 | >250 | >270 | >290 | >340 | >350 | >400 | >400 | >420 | |

| ho lelefatsa | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | |

| ho qhibiliha ntlha °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| karolelano ea ho khanna | 145 | 130 | 92 | 75 | 59 | 38 | 33 | 27 | 25 | 23 |

Terata ea ho futhumatsa ea motsoako oa nicr8020

1. Mabapi le terata ea Nichrome

Motsoako oa Nichrome o kenyelletsa nickel e hloekileng, motsoako oa NiCr, motsoako oa Fe-Cr-Al le motsoako oa koporo oa nickel.

Li-alloy tsa chrome tsa nikeli: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20, nikeli e hloekileng Ni200 le Ni201

2. Melemo e Meholo le Kopo

1. Motsoako oa nikeli-chromium, nikeli-chromium o nang le khanyetso e phahameng le e tsitsitseng, khanyetso ea ts'enyeho, khanyetso ea oxidation ea bokaholimo e ntle, e betere tlas'a mocheso o phahameng le matla a tšisinyeho ea lefatše, ductility e ntle, ts'ebetso e ntle le ho ts'oaroa habonolo.

2. Lihlahisoa tsa rona li sebetsa haholo indastering ea lik'hemik'hale, mokhoa oa tšepe, indasteri ea khalase, indasteri ea ceramic, sebaka sa lisebelisoa tsa lapeng le tse ling.

1) Sebopeho sa lik'hemik'hale:

| Letšoao | Sebopeho sa lik'hemik'hale | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| E seng ho feta | |||||||||

| Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | sala | ≤0.50 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | sala |

| Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | sala |

| Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | sala |

2) Boholo le Mamello

Ha sehlahisoa se le boemong ba “M”, se lokela ho lateloa ke GB/T1234-1995 e tloaelehileng.

1) Ho hanyetsa:

| Letšoao | Cr20Ni80 | Cr20Ni60 | Cr20Ni35 | Cr20Ni30 | ||

| Bophara ba mm | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| ho hanyetsa (20°C)uΩ·m | 1.09±0.05 | 1.13±0.05 | 1.12±0.05 | 1.15±0.05 | 1.04±0.05 | 1.06±0.05 |

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo