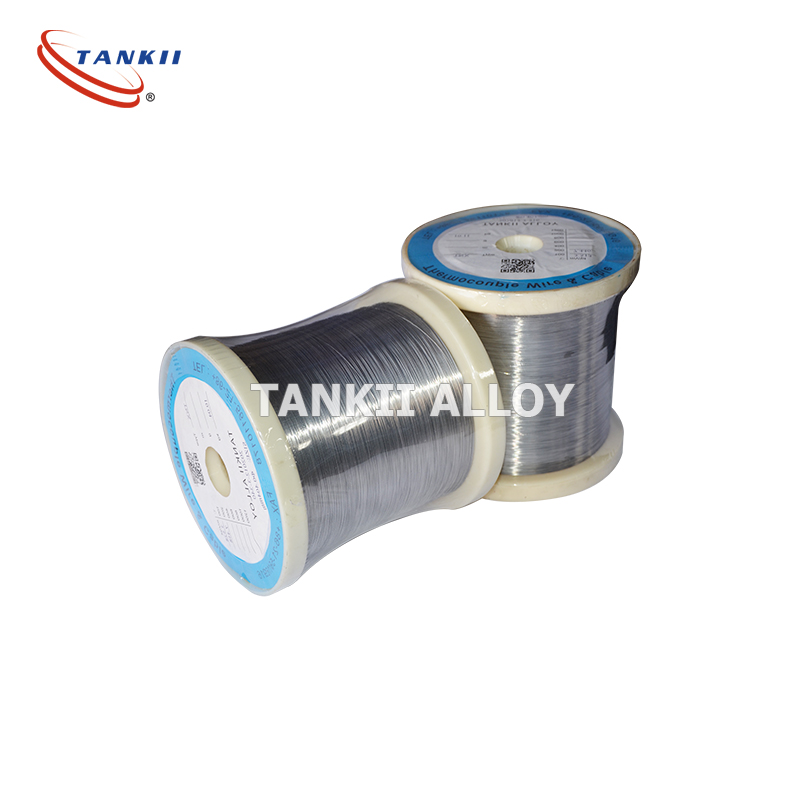

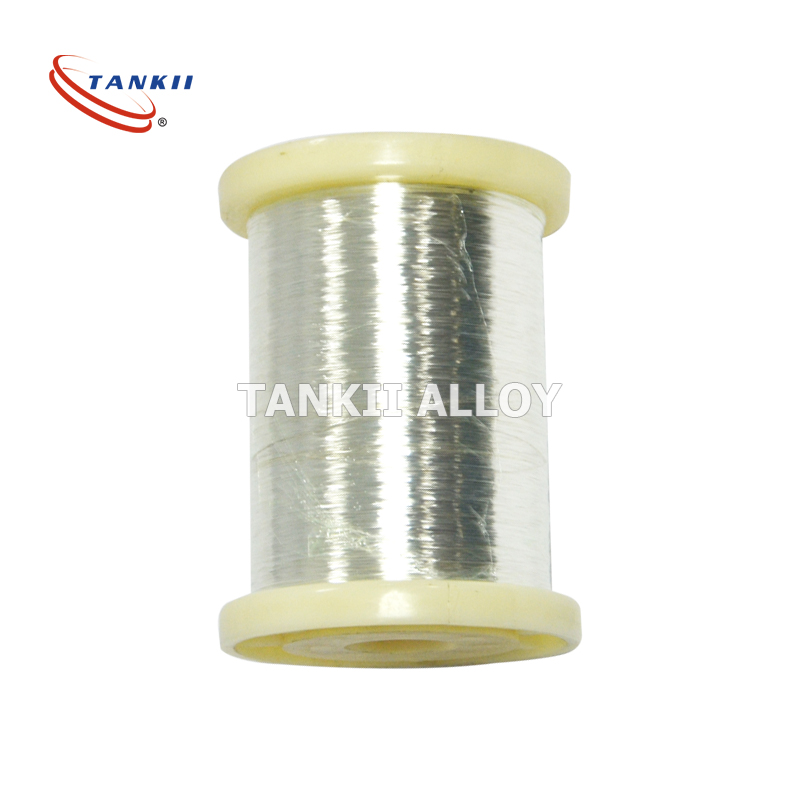

Terata e Hloekileng ea Nikele e Fanoang ka ho Otloloha ea Fektheri ea N4 Ni201

Leqephe la Nikele

Nickel ke tšepe e matla, e benyang, e tšoeu joaloka silevera e leng ntho ea bohlokoa bophelong ba rona ba letsatsi le letsatsi 'me e ka fumanoa nthong e' ngoe le e 'ngoe ho tloha libetering tse matlafatsang li-remote tsa thelevishene ea rona ho ea ho tšepe e sa hloekang e sebelisetsoang ho etsa lisinki tsa kichine ea rona.

Thepa:

1. Letšoao la Athomo: Ni

2. Nomoro ea Athomo: 28

3. Sehlopha sa Lielemente: Tšepe ea phetoho

4. Boima: 8.908g/cm3

5. Sebaka sa ho Qhibiliha: 2651°F (1455 °C)

6. Sebaka sa ho Belisa: 5275 °F (2913 °C)

7. Boima ba Moh: 4.0

Litšobotsi:

Nickel e matla haholo ebile e hanela mafome, e leng se etsang hore e be ntle haholo bakeng sa ho matlafatsa litšepe tse kopantsoeng. Hape e bonolo haholo ho e sebelisa ebile e bonolo ho e sebelisa, e leng thepa e lumellang litšepe tse ngata ho bōptjoa ka terata, lithupa, liphaephe le maqephe.

Tlhaloso

| Lesela la tšepe la nikeli | |

| Ntho | Boleng (%) |

| Bohloeki (%) | 99.97 |

| Cobalt | 0.050 |

| koporo | 0.001 |

| khabone | 0.003 |

| tšepe | 0.0004 |

| sebabole | 0.023 |

| arsenic | 0.001 |

| lead | 0.0005 |

| zinki | 0.0001 |

Likopo:

Nickel ke e 'ngoe ea litšepe tse sebelisoang haholo lefatšeng. Tšepe ena e sebelisoa lihlahisoa tse fapaneng tse fetang 300,000. Hangata e fumanoa litšepeng le litšepeng tse kopantsoeng tsa tšepe, empa e boetse e sebelisoa tlhahisong ea libeteri le limakenete tse sa feleng.

Boemo ba Khoebo

Shanghai Tankii Alloy Material Co., Ltd e shebane le tlhahiso ea motsoako oa Nichrome, terata ea thermocouple, motsoako oa FeCrAl, motsoako o nepahetseng, motsoako oa koporo oa nickel, motsoako oa spray oa mocheso jj ka mokhoa oa terata, lakane, theipi, moqhaka, molamu le poleiti.

Re se re ntse re e-na le setifikeiti sa sistimi ea boleng ba ISO9001 le tumello ea sistimi ea ts'ireletso ea tikoloho ea ISO14001. Re na le sete e felletseng ea phallo e tsoetseng pele ea tlhahiso ea ho hloekisa, ho fokotsa serame, ho hula le ho phekola mocheso jj. Re boetse re motlotlo ka bokhoni ba R&D bo ikemetseng.

Shanghai Tankii Alloy Material Co., Ltd e bokelletse boiphihlelo bo bongata ka lilemo tse fetang 35 tšimong ena. Lilemong tsena, ho ile ha sebelisoa litsebi tse fetang 60 tsa tsamaiso le litalenta tse phahameng tsa mahlale le theknoloji. Ba nkile karolo likarolong tsohle tsa bophelo ba k'hamphani, e leng se etsang hore k'hamphani ea rona e tsoele pele ho atleha le ho se hlōloe 'marakeng oa tlholisano.

Ho latela molao-motheo oa boleng ba pele, tšebeletso e tšepahalang, khopolo-taba ea rona ea tsamaiso e phehella boqapi ba theknoloji le ho theha lets'oao le holimo lefapheng la alloy. Re phehella boleng-the

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo