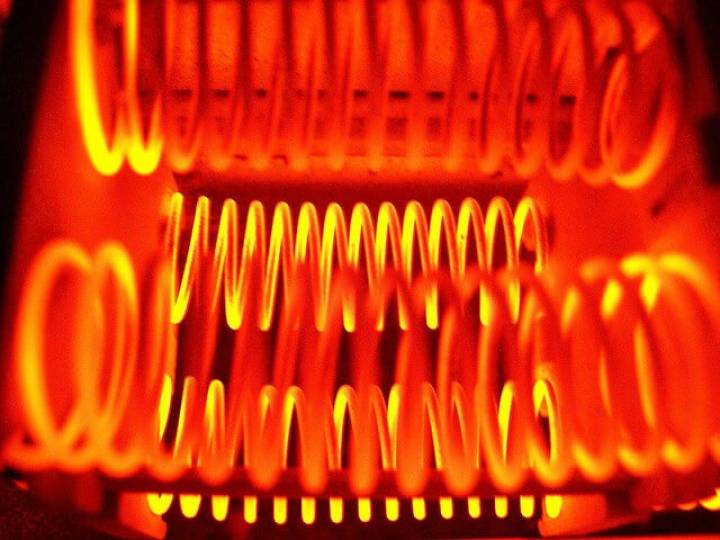

Khoele ea ho futhumatsa ea terata ea setofo sa motlakase sa FeCrAl 0Cr25Al5

Thepa e ka Sehloohong ea terata e hanyetsang ho futhumatsa

| Mofuta oa motsoako | Bophara (mm) | Ho hanyetsa (μΩm)(20°C) | Thapo Matla (N/mm²) | Ho lelefatsa(%) | Ho kobeha Linako | Boholo.Bo tsoelang pele Tšebeletso Mocheso(°C) | Bophelo ba ho Sebetsa (lihora) |

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

| LEBITSO | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| K'HEMIK'HELETE E KHŌLŌ | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| MOQHOBO | Re | e loketseng | e loketseng | e loketseng | e loketseng | e loketseng | e loketseng | e loketseng |

| Fe | Phomolo | Phomolo | Phomolo | Phomolo | Phomolo | Phomolo | Phomolo | |

| Nb0.5 | Mots'eanong 1.8-2.2 | |||||||

| MOCHESO O MOHOLO(oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| KGANYETSO 20oC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| BOTENYEHO(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| PHAPANO EA MOCHESO | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| SEKGAHLA(KJ/m·h·oC) | ||||||||

| sekhahla sa katoloso (α×10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| ntlha ea ho qhibiliha (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| matla a ho thapolla (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| bolelele(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| phapang ea sebaka(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| maqhubu a kobehang (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| thatafalo (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| sebopeho sa micrographic | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| thepa ea makenete | Matla a khoheli | Matla a khoheli | Matla a khoheli | Matla a khoheli | Matla a khoheli | Matla a khoheli | Matla a khoheli | |

| Bophara(mm) | Mamello (mm) | Bophara(mm) | Mamello (mm) |

| 0.03-0.05 | ± 0.005 | >0.50-1.00 | ± 0.02 |

| >0.05-0.10 | ± 0.006 | >1.00-3.00 | ± 0.03 |

| >0.10-0.20 | ± 0.008 | >3.00-6.00 | ± 0.04 |

| >0.20-0.30 | ± 0.010 | >6.00-8.00 | ± 0.05 |

| >0.30-0.50 | ± 0.015 | >8.00-12.0 | ± 0.4 |

| Botenya (mm) | Mamello (mm) | Bophara(mm) | Mamello (mm) |

| 0.05-0.10 | ± 0.010 | 5.00-10.0 | ± 0.2 |

| >0.10-0.20 | ± 0.015 | >10.0-20.0 | ± 0.2 |

| >0.20-0.50 | ± 0.020 | >20.0-30.0 | ± 0.2 |

| >0.50-1.00 | ± 0.030 | >30.0-50.0 | ± 0.3 |

| >1.00-1.80 | ± 0.040 | >50.0-90.0 | ± 0.3 |

| >1.80-2.50 | ± 0.050 | >90.0-120.0 | ± 0.5 |

| >2.50-3.50 | ± 0.060 | >120.0-250.0 | ± 0.6 |

Re moetsi oa terata ea ho hanyetsa mocheso e kenyeletsa

FeCrAL terata, NiCr terata, CuNi terata:

II Melemo e Meholo le Kopo

A. Paramethara ea 'mele:

1) Bophara ba terata: 0.025 ~ 15mm

2) Nikeli e hloekileng e na le bokhoni ba ho mamella mocheso o phahameng ntle le ho senyeha.

mocheso o ka bang 600°C

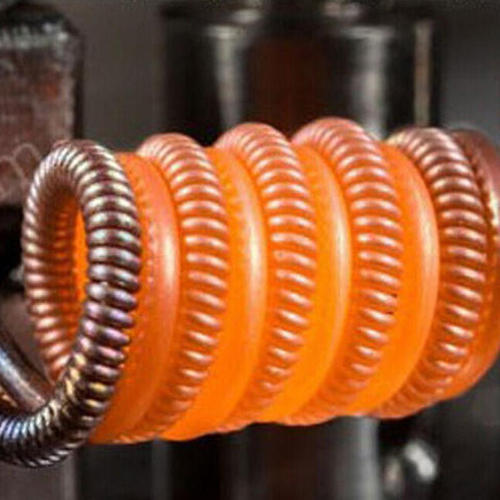

3) Terata ea nikeli e fumaneha ka moaho oa khoele e le 'ngoe kapa oa likhoele tse ngata. E fanoa ho tsoa setokong ebang ke e hlobotseng, kapa e koahetsoeng ka insulation

B. Litšobotsi:

1) Ho otloloha ho babatsehang

2) Boemo bo tšoanang le bo botle ba bokaholimo bo se nang matheba

3) Bokhoni bo botle ba ho etsa khoele

C. Litšebeliso tsa mantlha le morero o akaretsang:

1) Terata ena e ka boela ea sebelisoa haholo ho li-cap tsa transistor tse boletsoeng ka kakaretso, li-anode tsa li-tube tsa elektroniki,

lithapo tsa likarolo tsa elektroniki / lithapo tse kentsweng ka lere bakeng sa mabone le bakeng sa letlooeng la terata. E boetse e sebelisoa ka mokhoa oa ho hula bakeng sa mefuta e fapaneng ea

lits'ebetso tse kenyeletsang libeteri tsa Ni-Cd

2) E boetse e sebelisoa bakeng sa likhoele, Lead-in-Wire bakeng sa mabone, litšehetso tsa liphaephe tsa elektroniki, li-lead tse hokahanyang motlakase ka lesela la terata

moo mocheso o fetang oo koporo e loketseng ho o loha, ho loha terata

3) Ditshebediso tse tlwaelehileng di kenyeletsa: diphediso tsa dielemente tsa ho futhumatsa jwalo ka diontong, di-extruder tsa polasetiki, diontong.

Litšehetso tsa filament le lithapo tsa loto indastering ea mabone

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo