Terata ea motlakase e hanelang mocheso ea FeCrAl FeCr23Al5 A1 APM AF D Alloy

Terata ea motlakase e sa keneleng mocheso ea FeCrAl A1 APM AF D Alloy

Mabapi le Terata ea ho Futhumatsa ea Khanyetso:

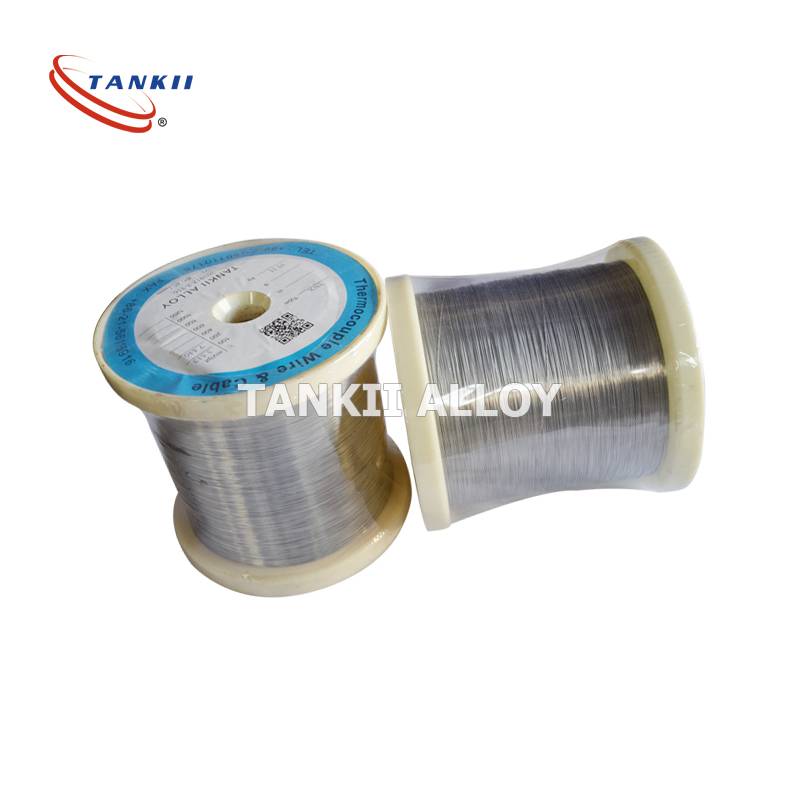

Re moetsi e moholo ka ho fetisisa oa litsebi oa alloy ea ho futhumatsa e hanyetsang Chaena, re ikhethile ka terata ea Ferro-Chrome (Fe-Cr-AL), terata ea Nickel-Chrome (Nichrome), terata ea Copper Nickel (Constantan), terata ea tšepe e sa ruseng le lihlahisoa tse amanang le eona ka li-alloy tse etselitsoeng ho fihlela litlhoko tse itseng tsa bareki.

Lintlha tsa boholo

| Lebitso la sehlahisoa | Mefuta ea boholo |

| Terata ea ho taka e batang | Bophara 0.03-7.5mm |

| Molamu oa terata o phuthoang ka mocheso | Bophara 8.0-12mm |

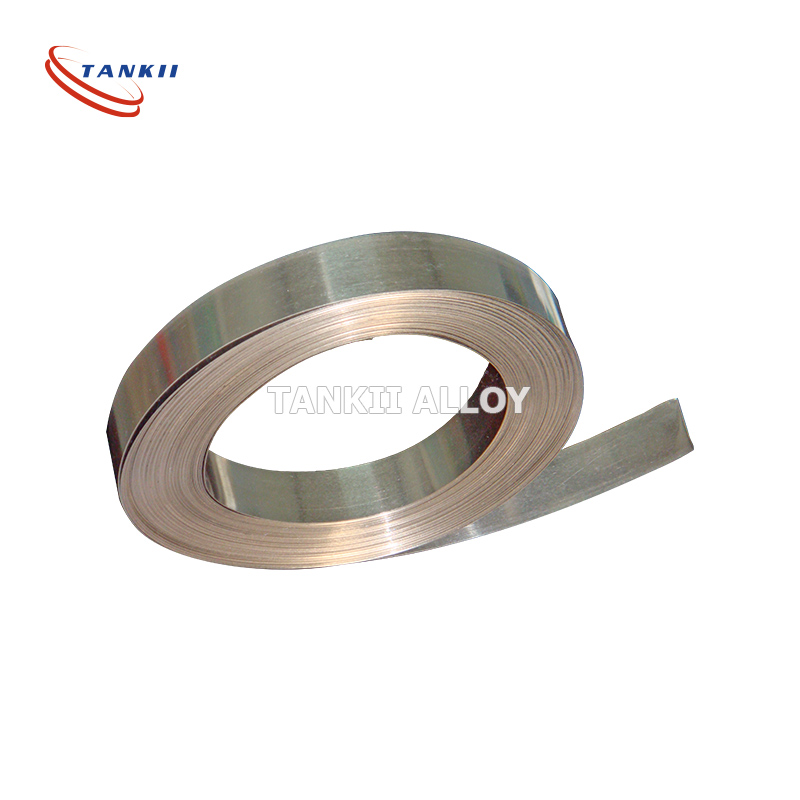

| Ribone | Botenya 0.05-0.35mm |

| Bophara 0.5.0-3.5mm | |

| Moqomo o phuthiloeng o batang | Botenya 0.5-2.5mm |

| Bophara 5.0-40mm | |

| moqolo o phutholohileng o chesang | Botenya 4-6mm |

| Bophara 15-40mm |

liparamente tsa motheo:

| liparamente tsa motheo | APMTM | FeCrAl | ||

| A-1 | AF | D | ||

| Mocheso o phahameng ka ho fetisisa o sebetsang o tsoelang pele | 1425 | 1400 | 1300 | 1300 |

| Sebopeho sa lik'hemik'hale tse tloaelehileng,% Cr | 22 | 22 | 22 | 22 |

| AI | 5.8 | 5.8 | 5.3 | 4.8 |

| Fe | metsoako | metsoako | metsoako | metsoako |

| Ni | - | - | - | - |

| Ho hanyetsa ho 20ºC, Ωmm-2mm-1 | 1.45 | 1.45 | 1.39 | 1.35 |

| bongata, g/cm3 | 7.1 | 7.1 | 7.15 | 7.25 |

| Koefficient ea katoloso ea mocheso K-1 20-750ºC | 14×10-6 | 14×10-6 | 14×10-6 | 14×10-6 |

| 20-1000ºC | 15×10-6 | 15×10-6 | 15×10-6 | 15×10-6 |

| Ho khanna ha mocheso 20ºC, Wm-1K-1 | 13 | 13 | 13 | 13 |

| Bokgoni bo itseng ba mocheso 20ºC, KJkg-1K-1 | 0.46 | 0.46 | 0.46 | 0.46 |

| Sebaka sa ho qhibilihaºC | 1500 | 1500 | 1500 | 1500 |

| Mohlomong litšobotsi tsa mechini | ||||

| Matla a ho tenyetseha, N mm-2 | 680 | 680 | 680 | 650 |

| Matla a tlhahiso, N mm-2 | 470 | 475 | 475 | 450 |

| Bothata, Hv | 230 | 230 | 230 | 230 |

| Ho roba bolelele,% | 20 | 18 | 18 | 18 |

| Matla a tensile a 900ºCT, N mm-2 | 40 | 34 | 37 | 34 |

| Matla a ho kheloha 800ºC | 11 | 6 | 8 | 6 |

| 1000ºC | 3.4 | 1 | 1.5 | 1 |

| Matla a khoheli | makenete (Ka mochesong oa 600ºC) | |||

| Ho ntša metsi, maemo a ho ntša oksijene | 0.7 | 0.7 | 0.7 | 0.7 |

Tlhaloso:

| Mofuta oa motsoako | Bophara | Ho hanyetsa | Thapo | Ho lelefatsa(%) | Ho kobeha | Boholo.Bo tsoelang pele | Bophelo ba ho Sebetsa |

| (mm) | (μΩm)(20°C) | Matla | Linako | Tšebeletso | (lihora) | ||

| (N/mm²) | Mocheso(°C) | ||||||

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

Molemo:

Motsoako oa nickelchromium o nang le khanyetso e phahameng le e tsitsitseng, khanyetso ea ts'enyeho, khanyetso ea oxidation ea bokaholimo e ntle, e betere tlas'a mocheso o phahameng le matla a tšisinyeho ea lefatše, ductility e ntle, ts'ebetso e ntle le ho tjheseletsa.

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo