Liphihlello tse kholo tsa indasteri ea lifofane li ke ke tsa aroloa ho nts'etsopele le tsoelo-pele theknolojing ea thepa ea lifofane. Bophahamo bo phahameng, lebelo le ho tsamaisoa ha lifofane tsa ntoa ho hloka hore thepa ea sebopeho sa sefofane e netefatse matla a lekaneng hammoho le litlhoko tsa ho tiea. Thepa ea enjene e hloka ho fihlela tlhoko ea ho hanyetsa mocheso o phahameng, li-alloy tsa mocheso o phahameng, thepa e kopantsoeng e thehiloeng ho ceramic ke thepa ea mantlha.

Tšepe e tloaelehileng e nolofala ka holimo ho 300℃, e leng se etsang hore e se ke ea tšoaneleha bakeng sa libaka tse nang le mocheso o phahameng. Ha ho phehelloa katleho e phahameng ea phetoho ea matla, ho hlokahala mocheso o phahameng le o phahameng oa ts'ebetso lefapheng la matla a enjene ea mocheso. Li-alloy tsa mocheso o phahameng li entsoe bakeng sa ts'ebetso e tsitsitseng mochesong o fetang 600℃, 'me theknoloji e ntse e tsoela pele ho fetoha.

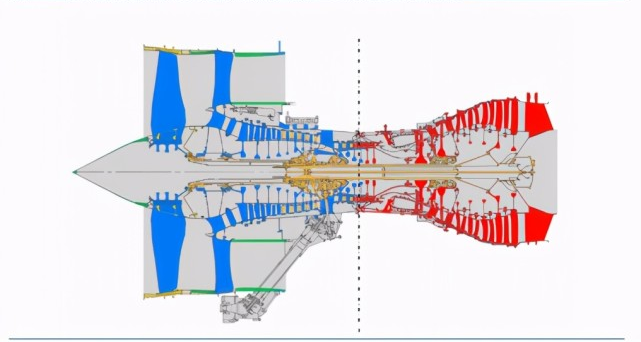

Di-alloy tsa mocheso o phahameng ke thepa ea bohlokoa bakeng sa lienjine tsa lifofane, tse arotsoeng ka li-alloy tsa mocheso o phahameng tse thehiloeng tšepeng, tse thehiloeng nickel ke likarolo tse ka sehloohong tsa motsoako. Li-alloy tsa mocheso o phahameng li 'nile tsa sebelisoa lienjineng tsa lifofane ho tloha ha li thehoa,' me ke thepa ea bohlokoa tlhahisong ea lienjine tsa lifofane. Boemo ba ts'ebetso ea enjene bo itšetlehile haholo ka boemo ba ts'ebetso ea thepa ea alloy ea mocheso o phahameng. Lienjineng tsa kajeno tsa lifofane, bongata ba thepa ea alloy ea mocheso o phahameng bo etsa karolo ea 40-60 lekholong ea boima bohle ba enjene, 'me bo sebelisoa haholo bakeng sa likarolo tse' nè tse ka sehloohong tsa ho chesa: likamore tsa ho chesa, litataiso, mahare a turbine le li-disc tsa turbine, 'me ho phaella moo, e sebelisoa bakeng sa likarolo tse kang limakasine, masale, likamore tsa ho chesa tjhaja le li-nozzle tsa mohatla.

(Karolo e khubelu ea setšoantšo e bontša metsoako ea mocheso o phahameng)

Li-alloy tse nang le mocheso o phahameng tse thehiloeng ho nikeli Ka kakaretso e sebetsa ho 600 ℃ kaholimo ho maemo a khatello e itseng, ha e na feela ho hanyetsa ho oxidation le ho bola ha mocheso o phahameng, 'me e na le matla a phahameng a mocheso o phahameng, matla a ho creep le matla a mamello, hammoho le ho hanyetsa mokhathala o motle. E sebelisoa haholo-holo lefapheng la lifofane le lifofane tlas'a maemo a mocheso o phahameng, likarolo tsa sebopeho, tse kang mahare a enjene ea lifofane, li-disc tsa turbine, likamore tsa ho tuka le tse ling. Li-alloy tse thehiloeng ho nickel tse nang le mocheso o phahameng li ka aroloa ka li-alloy tse fetotsoeng tsa mocheso o phahameng, li-alloy tse entsoeng ka mocheso o phahameng le li-alloy tse ncha tsa mocheso o phahameng ho latela ts'ebetso ea tlhahiso.

Ka mocheso o sebetsang oa motsoako o sa keneleng mocheso o phahame le ho feta, likarolo tse matlafatsang motsoakong li ntse li eketseha, ha motsoako o rarahane haholoanyane, e leng se etsang hore li-alloy tse ling li ka sebelisoa feela boemong ba ho lahla, li ke ke tsa fetoloa ts'ebetso e chesang. Ho feta moo, keketseho ea likarolo tsa ho kopanya e etsa hore li-alloy tse thehiloeng ho nickel li tiee ka karohano e tebileng ea likarolo, e leng se fellang ka ho se tšoane ha mokhatlo le thepa.Tšebeliso ea ts'ebetso ea tšepe ea phofo ho hlahisa li-alloy tsa mocheso o phahameng, e ka rarolla mathata a boletsoeng ka holimo.Ka lebaka la likaroloana tse nyane tsa phofo, lebelo la ho pholisa phofo, ho felisa karohano, ho ntlafala ha ho sebetsa ha mocheso, motsoako oa pele oa ho lahla ho fetoha o chesang o sebetsang oa li-alloy tsa mocheso o phahameng, matla a tlhahiso le thepa ea mokhathala lia ntlafala, motsoako oa phofo oa mocheso o phahameng bakeng sa tlhahiso ea li-alloy tse matla a holimo o hlahisitse mokhoa o mocha.

Nako ea poso: Pherekhong-19-2024