Phosphor Bronze-C/Ercusn-C/Scu5210 Litšepe tsa Koporo tse kopantsoeng tsa ho tjheseletsa terata

Sebopeho sa lik'hemik'hale:

| Motsamaisi maemo a tloaelehileng | Tlhophiso nomoro | Motsoako nomoro | Cu | AI | Fe | Mn | Ni | P | Pb | Si | Sn | Zn | Kakaretso ea chelete likarolo tse ling |

| ISO24373 | Cu5210 | CuSn8P | bal. | - | 0.1 | - | 0.2 | 0.01-0.4 | 0.02 | - | 7.5-8.5 | 0..2 | 0.2 |

| GB/T9460 | SCu5210 | CuSn8P | bal. | - | boholo ba 0.1 | - | boholo ba 0.2 | 0.01-0.4 | boholo ba 0.02 | - | 7.5-8.5 | boholo ba 0.2 | boholo ba 0.2 |

| BS EN14640 | Cu5210 | CuSn9P | bal. | - | 0.1 | - | - | 0.01-0.4 | 0.02 | - | 7.5-8.5 | 0.2 | 0.5 |

| AWS A5.7 | C52100 | ERCuSn-C | bal. | 0.01 | 0.10 | - | - | 0.10-0.35 | 0.02 | - | 7.5-8.5 | 0.2 | 0.50 |

Thepa ea 'mele ea thepa:

| Botenya | Kg/m3 | 8.8 |

| Sebaka sa ho qhibiliha | ºC | 875-1025 |

| Ho khanna ha mocheso | W/mK | 66 |

| Ho tsamaisa motlakase | Semi/mm2 | 6-8 |

| Tekanyo e sebetsang ea katoloso ea mocheso | 10-6/K(20-300ºC) | 18.5 |

Litekanyetso tse tloaelehileng tsa tšepe ea weld:

| Ho lelefatsa | % | 20 |

| Matla a tšepe | N/mm² | 260 |

| Mosebetsi oa ho ama bareng ka mokhoa o sa reroang | J | 32 |

| Bothata ba Brinell | HB 2.5/62.5 | 80 |

Likopo:

Motsoako oa koporo oa tin o nang le bothata bo eketsehileng ba peresente ea tin bakeng sa ho tjheseletsa ka holimo. E loketse haholo bakeng sa ho tjheseletsa thepa ea koporo, joalo ka koporo, li-bronze tsa tin, haholo-holo e sebelisetsoang ho kopanya li-alloy tsa koporo tsa zinki le litšepe. E loketse ho tjheseletsa li-bronze tse entsoeng ka cast le bakeng sa ho kopanya ka ontong. Bakeng sa ho tjheseletsa ka mekhahlelo e mengata holim'a tšepe, ho tjheseletsa ka arc e pulsed ho khothaletsoa. Bakeng sa likarolo tse kholo tsa mosebetsi ho khothaletsoa ho futhumatsa pele.

Boelana:

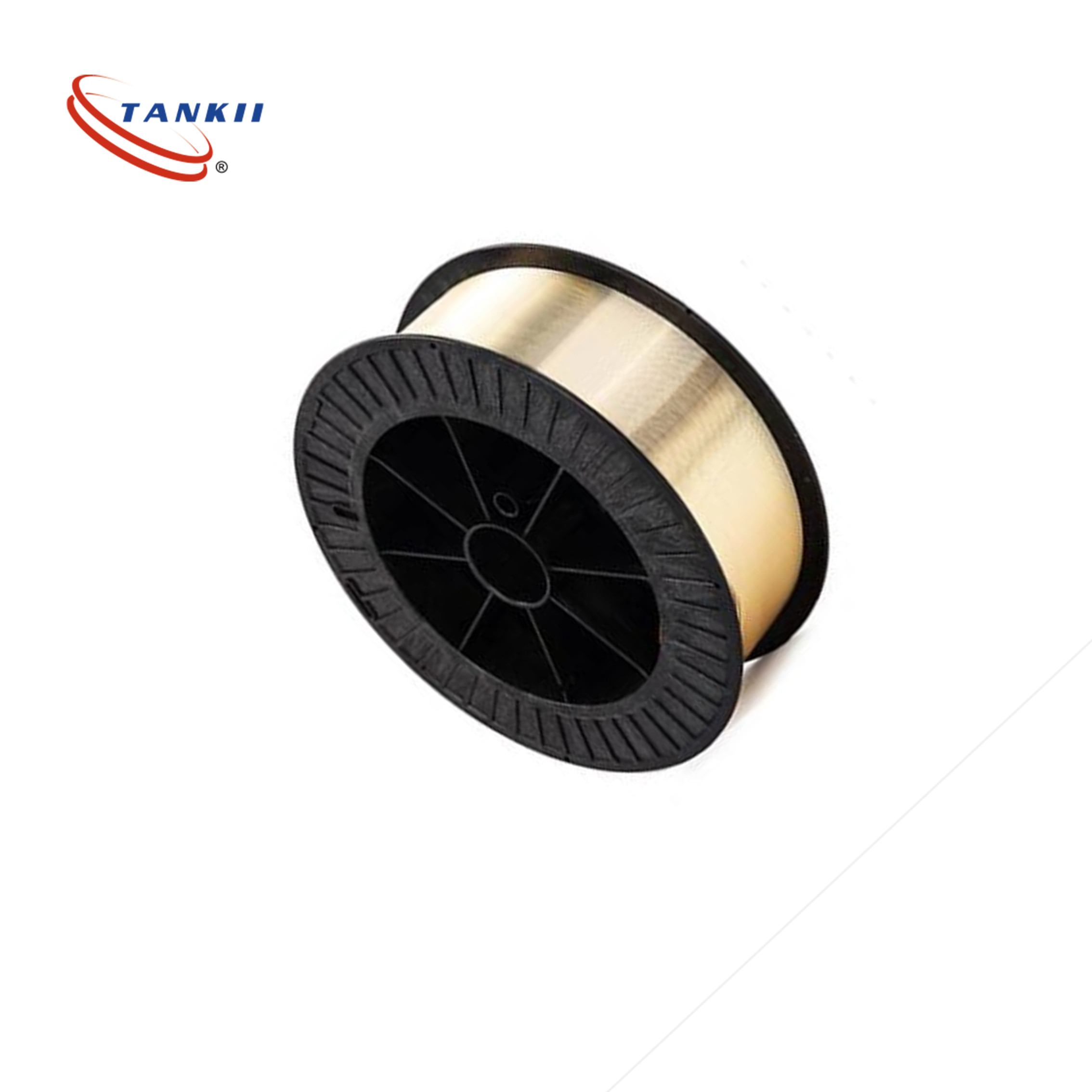

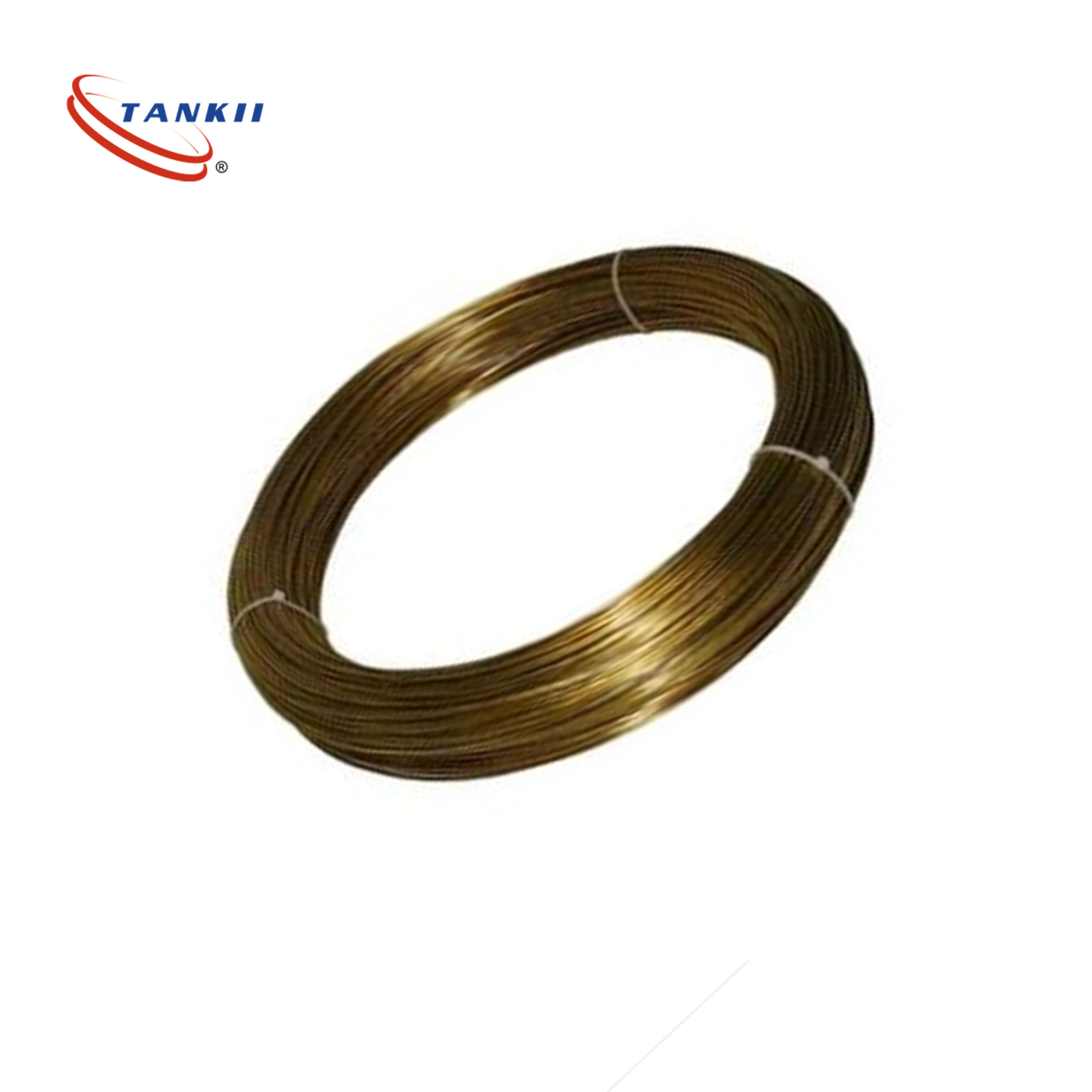

Bophara: 0.80 – 1.00 – 1.20 – 1.60 – 2.40

Li-spool: D100, D200, D300, K300, KS300, BS300

Lithupa: 1.20 – 5.0 mm x 350mm-1000 mm

Li-electrode lia fumaneha.

Litlolo tse ling ha ho kopuoa.

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo