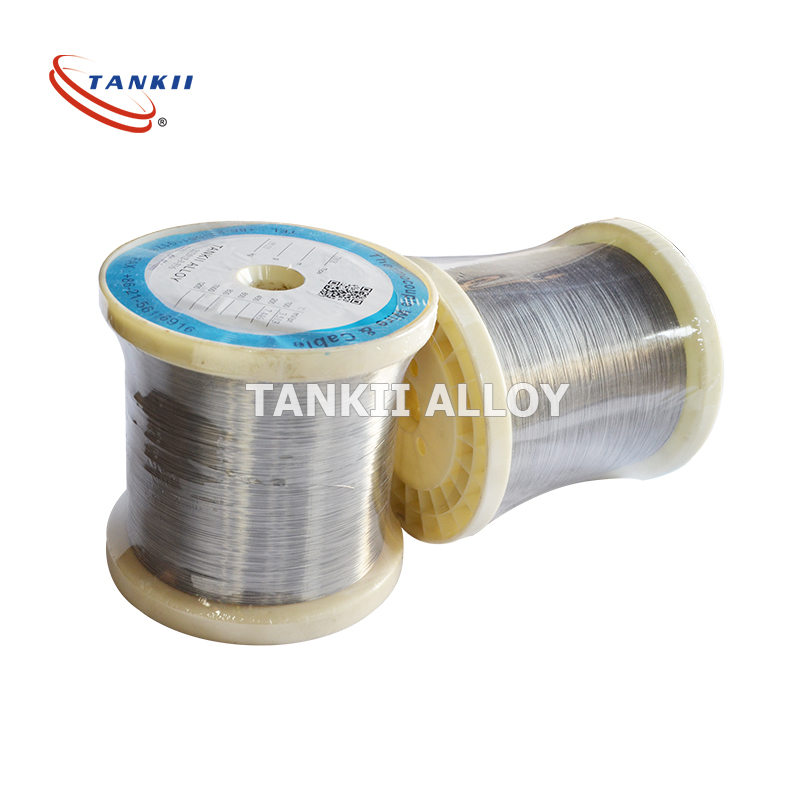

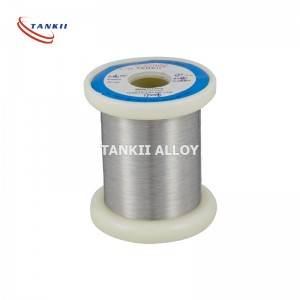

Radiator e Hanelang Mocheso 0cr25al5 Terata ea Alloy Terata ea ho hanyetsa fecral

Radiator Resistance Heating wire Fecral 0cr25al5 Alloy ka 'Mala o moputsoa oa silevera

1. Tlhaloso e qaqileng

Motsoako oa FeCrAl, 1Cr13Al4,0Cr23Al5, 0Cr25Al5, 0Cr20Al6RE, 0Cr21Al6Nb, 0Cr27Al7Mo2

Motsoako oa FeCrAl ke motsoako oa ferritic iron-chromium-aluminium (motsoako oa FeCrAl) o sebelisoang lits'ebetsong tsa arc le spray ea malakabe. Motsoako ona o hlahisa masela a teteaneng, a khomarelang hantle, a hanelang oxidation le mafome a mocheso o phahameng.

Tšebeliso kapa Matlotlo: Terata ea fafatsa e nang le matla a matle a ho kopanya. Mealo e fafatsang ea thepa ena e hanela liphetoho mochesong o phahameng 'me e sebelisoa e le lera la buffer bakeng sa metsoako e meng eohle ea fafatsa.

0Cr25Al5

0Cr25Al5 ke motsoako oa ferritic iron-chromium-aluminium (motsoako oa FeCrAl) bakeng sa tšebeliso lits'ebetsong tsa arc le spray ea malakabe. Motsoako ona o hlahisa masela a teteaneng, a kopanyang hantle, a hanelang oxidation le mafome a mocheso o phahameng.

2. Thepa ea Mekaniki

| Tempera e Phahameng ea Tšebeletso e Tsoelang Pele | 980ºC |

| Ho tsitsa ha mocheso ho 20ºC | 1.28 ohm mm2/m |

| Botenya | 7.4 g/cm3 |

| Ho khanna ha mocheso | 52.7 KJ/m@h@ºC |

| Katoloso ea Thermal e sebetsang hantle | 15.4×10-6/ºC |

| Sebaka sa ho Qhibiliha | 1450ºC |

| Matla a tšepe | 637~784 Mpa |

| Ho lelefatsa | Bonyane 12% |

| Phapang ea Karolo Sekhahla sa ho Fokotsa | 65~75% |

| Maqhubu a Kobehang Khafetsa | Bonyane ka makhetlo a 5 |

| Nako ea Tšebeletso e Tsoelang Pele | - |

| Bothata | 200-260HB |

| Sebopeho sa Micrographic | Ferrite |

| Thepa ea Magnetic | Matla a khoheli |

3. Likarolo

Tshebetso e tsitsitseng; Thibelo ea oxidation; Khanyetso ea mafome; Coefficient e tlase ea katoloso; Botsitso ba mocheso o phahameng; Bokhoni bo botle ba ho etsa coil; Mojaro o phahameng oa bokaholimo; Boemo bo tšoanang le bo botle ba bokaholimo bo se nang matheba

4. Lihlahisoa le lits'ebeletso

1). Pase: Setifikeiti sa ISO9001, le setifikeiti sa SO14001;

2). Litšebeletso tsa tefiso kamora thekiso;

3). Odara e nyane e amohetsoe;

4). Thepa e tsitsitseng mochesong o phahameng;

5). Thomello e potlakileng.

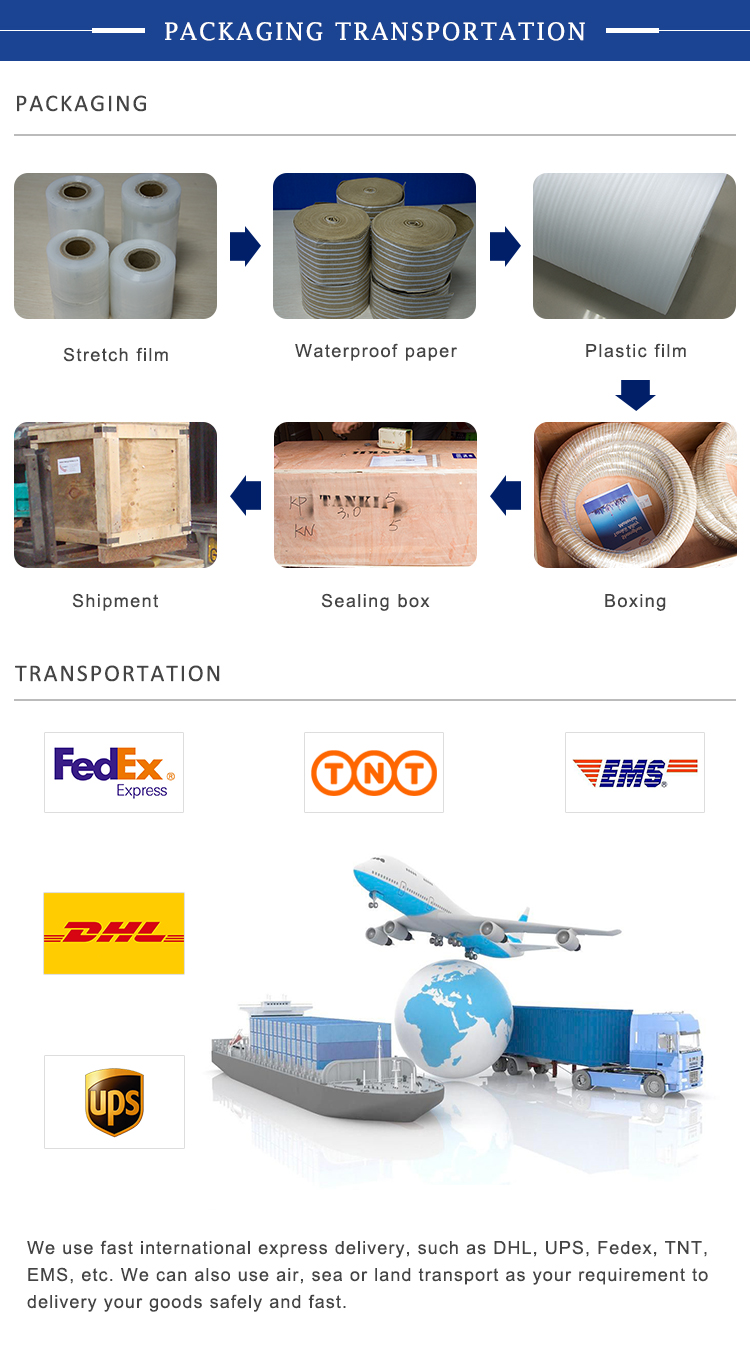

6). Sekotjana, khoele, lebokose, mokotlana oa lepolanka o nang le filimi ea polasetiki kapa pampiri e 'ngoe ea ho phuthela ho latela litlhoko tsa moreki.

5. Ntlha ea Mocheso ea ho Hanela Motlakase

| 20ºC | 100ºC | 200ºC | 300ºC | 400ºC | 500ºC | 600ºC | 700ºC | 800ºC | 900ºC | 1000ºC |

| 1 | 1.005 | 1.014 | 1.028 | 1.044 | 1.064 | 1.090 | 1.120 | 1.132 | 1.142 | 1.150 |

6. Sebopeho sa Lik'hemik'hale

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Tse ling | ||

| Boholo | |||||||||||

| 0.12 | 0.025 | 0.025 | 0.70 | Boholo 1.0 | 13.0~15.0 | Boholo 0.60 | 4.5~6.0 | Bala. | - | ||

Haeba o na le thahasello, ka kopo o se ke wa tsilatsila ho ikopanya le rona.

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo