Motsoako oa CuNi oa Motlakase oa Spiral 1 - 5 Mohm bakeng sa Lisebelisoa tsa ho Futhumatsa tsa Air Conditioner

Motsoako oa Nicr oa Motlakase oa Spiral 1 - 5 Mohm bakeng sa Lisebelisoa tsa ho Futhumatsa tsa Air Conditioner

1.Tlhaloso e Akaretsang ea Boitsebiso

Constantanke motsoako oa koporo-nickel o tsejoang hape e leEureka,Tsoela peleleSekepeHangata e na le koporo ea 55% le nickel ea 45%. Tšobotsi ea eona e ka sehloohong ke ho hanyetsa ha eona, e leng ntho e sa fetoheng holim'a mefuta e mengata ea mocheso. Li-alloy tse ling tse nang le li-coefficients tse tšoanang tsa mocheso o tlase lia tsejoa, joalo ka manganin (Cu).86Mn12Ni2).

Bakeng sa tekanyo ea mefuta e meholo haholo, 5% (50 000 microstrian) kapa ho feta, annealed constantan (P alloy) ke thepa ea gridi eo ka tloaelo e khethiloeng. Constantan ka sebopeho sena e matla haholo.ductile; 'me, ka bolelele ba gauge ba lisenthimithara tse 0.125 (3.2 mm) le ho feta, e ka hatelloa ho fihlela ho >20%. Leha ho le joalo, ho lokela ho hopoloa hore tlas'a mefuta e phahameng ea potoloho, motsoako oa P o tla bontša phetoho e sa feleng ea resistivity ka potoloho e 'ngoe le e 'ngoe, 'me o bake phetoho e tsamaellanang.lefelaphetoho ea tekanyo ea khatello. Ka lebaka la tšobotsi ena, le tšekamelo ea ho hloleha ha gridi pele ho nako ka ho thatafatsa khafetsa, motsoako oa P ha o khothalletsoe hangata bakeng sa lits'ebetso tsa khatello ea potoloho. Motsoako oa P o fumaneha ka linomoro tsa STC tsa 08 le 40 bakeng sa tšebeliso litšepeng le polasetiking, ka ho latellana.

2. Selelekela sa Selemo le lits'ebetso

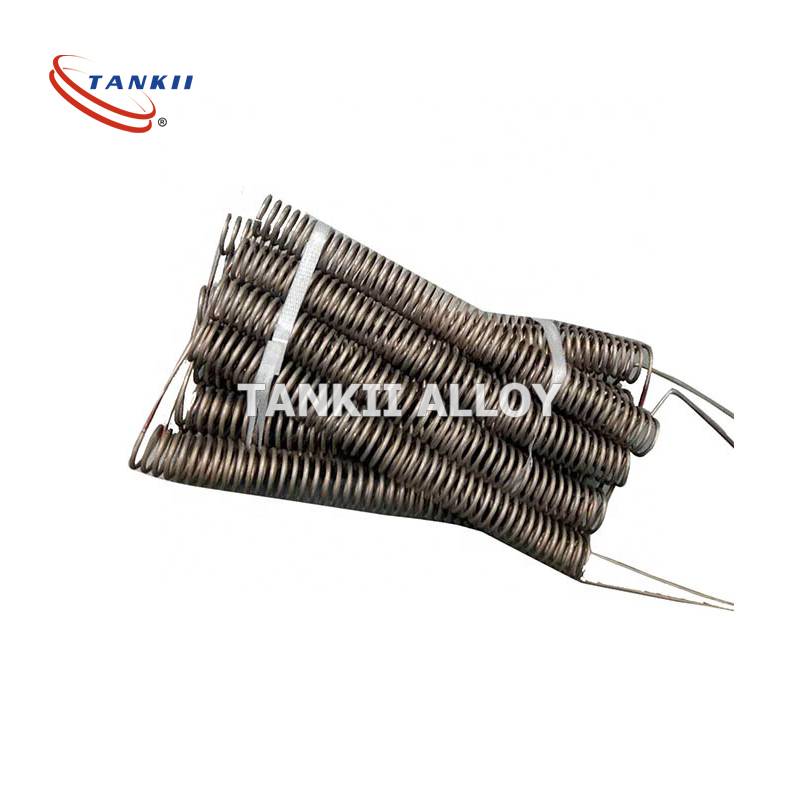

Seliba sa ho rota se potolohang, kapa sehla sa moriri, ka hara oache ea alamo.

Seliba se nang le modumo o phahameng. Tlas'a kgatello, dikhoele di thella hodima tse ding, kahoo di fana ka leeto le lelelele.

Liliba tsa volute tse otlolohileng tsa tanka ea Stuart

Li-spring tsa khatello ka har'a sesebelisoa sa ho kgutlisa molumo se mennweng.

Bara ea torsion e sothehileng tlas'a mojaro

Lekhasi le hlaha terakeng

Li-spring li ka aroloa ho latela hore na matla a mojaro a sebelisoa joang ho tsona:

Seliba sa kgatello/katoloso – seliba se etselitsoe ho sebetsa ka mojaro wa kgatello, kahoo seliba se a otlolla ha mojaro o sebediswa ho sona.

Seliba sa kgatello – se etselitsoe ho sebetsa ka mojaro wa kgatello, kahoo seliba se kgutshwane ha mojaro o sebediswa ho sona.

Seliba sa ho kgutlisa – ho fapana le mefuta e ka hodimo eo ho yona mojaro e leng matla a axial, mojaro o sebediswang seliba sa ho kgutlisa ke matla a ho kgutlisa kapa a ho sotha, mme pheletso ya seliba e potoloha ka sekhutlo ha mojaro o sebediswa.

Moroalo o tshehetswang ke selemo o sa fetoheng o dula o tshwana nakong yohle ya potoloho ya ho kgeloha.

Selemo se feto-fetohang – khanyetso ea koili ho jara e fapana nakong ea khatello.

Seliba sa ho thatafala se feto-fetohang – khanyetso ea koili ho jara e ka fetoloa ka mokhoa o feto-fetohang mohlala ke sistimi ea taolo, mefuta e meng ea liliba tsena le eona e fapana bolelele ba tsona ka hona e fana ka bokhoni ba ho tsamaisa motlakase.

Li ka boela tsa aroloa ho latela sebopeho sa tsona:

Seliba se bataletseng – mofuta ona o entsoe ka tšepe ea seliba se bataletseng.

Seliba se entsoeng ka mochini – mofuta ona oa selemo o etsoa ka mochini o sebelisang lepolanka le/kapa ho sila ho fapana le ho sebelisa mochini o kobehileng. Kaha o entsoe ka mochini, selemo se ka kenyelletsa likarolo tse ling ho phaella ho karolo ea elastic. Liliba tse entsoeng ka mochini li ka etsoa maemong a tloaelehileng a mojaro oa khatello/katoloso, torsion, jj.

Seliba sa noha – terata e teteaneng e kobehileng ka zig-zag – hangata se sebediswang ka thepa ya ka tlung/fenishareng ya sejwalejwale.

3. Sebopeho sa Lik'hemik'hale le Thepa e ka Sehloohong ea Motsoako oa Cu-Ni Low Resistance

| Sehlopha sa Matlo | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Sebopeho se Seholo sa Lik'hemik'hale | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bala | Bala | Bala | Bala | Bala | Bala | |

| Mocheso o Phahameng oa Tšebeletso o Tsoelang Pele (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Ho tiea ha matla ho 20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Botenya (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Motlakase oa Thermal (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Matla a ho Tenyetseha (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF khahlano le Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Sebaka se Hakanyetsoang sa ho Qhibiliha(oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Sebopeho sa Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Thepa ea Magnetic | eseng | eseng | eseng | eseng | eseng | eseng | |

| Sehlopha sa Matlo | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Sebopeho se Seholo sa Lik'hemik'hale | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bala | Bala | Bala | Bala | Bala | Bala | |

| Mocheso o Phahameng oa Tšebeletso o Tsoelang Pele (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Ho tiea ha matla ho 20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Botenya (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Motlakase oa Thermal (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Matla a ho Tenyetseha (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF khahlano le Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Sebaka se Hakanyetsoang sa ho Qhibiliha(oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Sebopeho sa Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Thepa ea Magnetic | eseng | eseng | eseng | eseng | eseng | eseng | |

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo