Khoele ea Selemo

ptlhaloso ea sehlahisoa

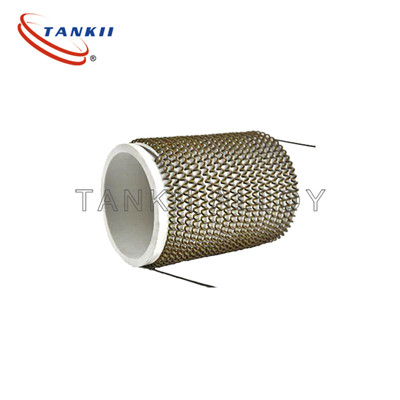

Khamphani ea rona e hlahisa lithapo tsa motlakase tsa tšepe-chromium-aluminium le nickel-chromium tsa boleng bo holimo, tse amohelang matla a terata ea sebōpi e laoloang ke khomphutha 'me li kobeha sebopeho ke mochini o kobehang o iketsang ka lebelo le phahameng. Litšobotsi tsa sehlahisoa sena: ho hanyetsa mocheso o phahameng, ho futhumatsa ka potlako, bophelo bo bolelele ba tšebeletso, ho hanyetsa ho tsitsitseng, ho kheloha ha motlakase o monyenyane, ho otlolla ho tšoanang ka mor'a ho otlolla, bokaholimo bo khanyang le bo hloekileng; bo sebelisoa haholo liontong tse nyane tsa motlakase, liontong tse se nang mokelikeli, lisebelisoa tsa ho futhumatsa le ho futhumatsa moea, liontong tse fapaneng, liphaephe tsa ho futhumatsa tsa motlakase le lisebelisoa tsa ntlo, jj. Lithapo tse fapaneng tsa lionto tsa indasteri le tsa sechaba tse seng tsa maemo li ka etsoa le ho hlahisoa ho latela litlhoko tsa basebelisi.

| Matla a W | Vselemo sa khale V | Bophara ba mm | OD mm | Length (Referense) mm | Wdigrama tse robeli |

| 300 | 220 | 0.25 | 3.7 | 122 | 1.9 |

| 500 | 220 | 0.35 | 3.9 | 196 | 4.3 |

| 600 | 220 | 0.40 | 4.2 | 228 | 6.1 |

| 800 | 220 | 0.50 | 4.7 | 302 | 11.1 |

| 1000 | 220 | 0.60 | 4.9 | 407 | 18.5 |

| 1200 | 220 | 0.70 | 5.6 | 474 | 28.5 |

| 1500 | 220 | 0.80 | 5.8 | 554 | 39.0 |

| 2000 | 220 | 0.95 | 6.1 | 676 | 57.9 |

| 2500 | 220 | 1.10 | 6.9 | 745 | 83.3 |

| 3000 | 220 | 1.20 | 7.1 | 792 | 98.3 |

Mocheso le sebopeho sa lik'hemik'hale tsa terata ea ho futhumatsa

| Sehlopha | Bongata. E tsoela pele Temperature ea ho Sebetsa. | Cr% | Ni% | Al% | Fe% | Phello ea% | Nb% | Mo% |

| Cr20Ni80 | 1200℃ | 20~23 | Bala. |

|

|

|

|

|

| Cr30Ni70 | 1250℃ | 28~31 | Bala. |

|

|

|

|

|

| Cr15Ni60 | 1150℃ | 15-18 | 55~61 |

| Bala. |

|

|

|

| Cr20Ni35 | 1100℃ | 18~21 | 34~37 |

| Bala. |

|

|

|

| TANKII APM | 1425℃ | 20.5~23.5 |

| 5.8 | Bala. | / |

|

|

| 0Cr27Al7Mo2 | 1400℃ | 26.5~27.8 |

| 6-7 | Bala. |

|

| 2 |

| 0Cr21Al6Nb | 1350℃ | 21~23 |

| 5-7 | Bala. |

| 0.5 |

|

| 0Cr25Al5 | 1250℃ | 23~26 |

| 4.5~6.5 | Bala. |

|

|

|

| 0Cr23Al5Y | 1300℃ | 22.5~24.5 |

| 4.2~5.0 | Bala. |

|

|

|

| 0Cr19Al3 | 1100℃ | 18~21 |

| 3~4.2 | Bala. |

|

|

|

Thepa ea mantlha ea tekheniki ea terata ea alloy ea FeCrAl:

①Mocheso oa tšebeliso o phahame, mocheso oa tšebeliso oa terata ea tšepe-chromium aluminium alloy sepakapakeng o ka fihla ho 1300℃;

②Bophelo ba tšebeletso e telele;

③Mojaro o lumelletsoeng oa bokaholimo o moholo;

⑤Matla a khoheli a itseng a manyane ho feta motsoako oa nickel-chromium; ④Khanyetso ea oxidation e ntle, 'me filimi ea AI2O3 e entsoeng ka mor'a oxidation e na le khanyetso e ntle ea lik'hemik'hale le khanyetso e phahameng;

⑥Ho hanyetsa ho hoholo;

⑦Khanyetso e ntle ea sebabole;

⑧Theko e tlase haholo ho feta ea motsoako oa nickel-chromium;

⑨Bothata ke hore ha mocheso o ntse o eketseha, o bontša ho ba bonolo, 'me matla a mochesong o phahameng a tlaase.

Litšobotsi tsa terata ea setofo sa motlakase ea nickel-chromium ke:

① Matla a phahameng mochesong o phahameng;

②E pholise kamora ho sebelisoa nako e telele, thepa e ke ke ea robeha habonolo;

③Ho ntšoa ha motsoako oa Ni-ming o nang le oxidized ka botlalo ho phahame ho feta ha motsoako oa Fe-Cr-Al;

④Ha ho na makenete;

⑤Ntle le sepakapaka sa sebabole, se na le khanyetso e betere ea ts'enyeho

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo