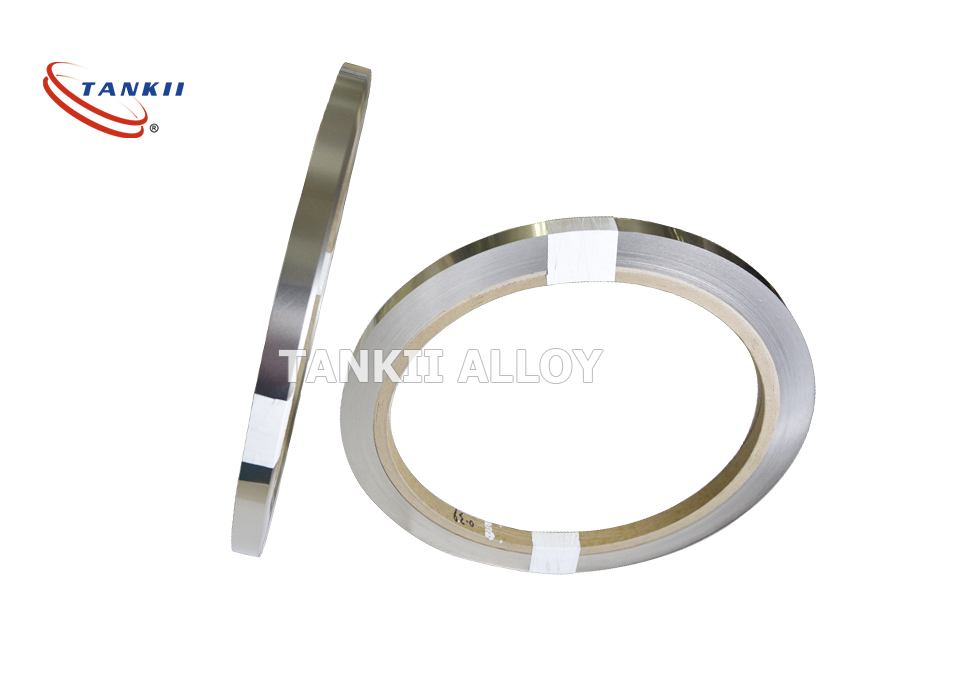

Khoele ea Strip ea terata ea FeCrAl e hanyetsang ea botenya ba 0.05mm

Motsoako oa FeCrAlFoil/Strip Coil 0.05mm Botenya bakeng sa Substrate tsa Tšepe tsa Lehe la Mahe a Linotši

Dikahare tse phahameng tsa aluminium, hammoho le dikahare tse phahameng tsa chromium di baka hore mocheso wa sekala o eketsehe ho fihlela ho 1425 C (2600F); Tlas'a sehlooho, ho hanyetsa mocheso, tsenaMotsoako oa FeCrAls li bapisoa le metsoako ea motheo ea Fe le Ni e sebelisoang hangata. Joalokaha ho ka bonoa tafoleng eo,Motsoako oa FeCrAlLi na le thepa e phahameng ha li bapisoa le li-alloy tse ling libakeng tse ngata.

Ho lokela ho hlokomeloa hore, nakong ea maemo a mocheso o fapanyetsanang, ho eketsoa ha yttrium ho motsoako oa AF oo hape o tsejoang e le metsoako ea Fecralloys, ho ntlafatsa ho khomarela ha oxide e sireletsang, ho etsa hore bophelo ba tšebeletso ea likarolo tse motsoakong oa AF bo be telele ho feta ba sehlopha sa A-1.

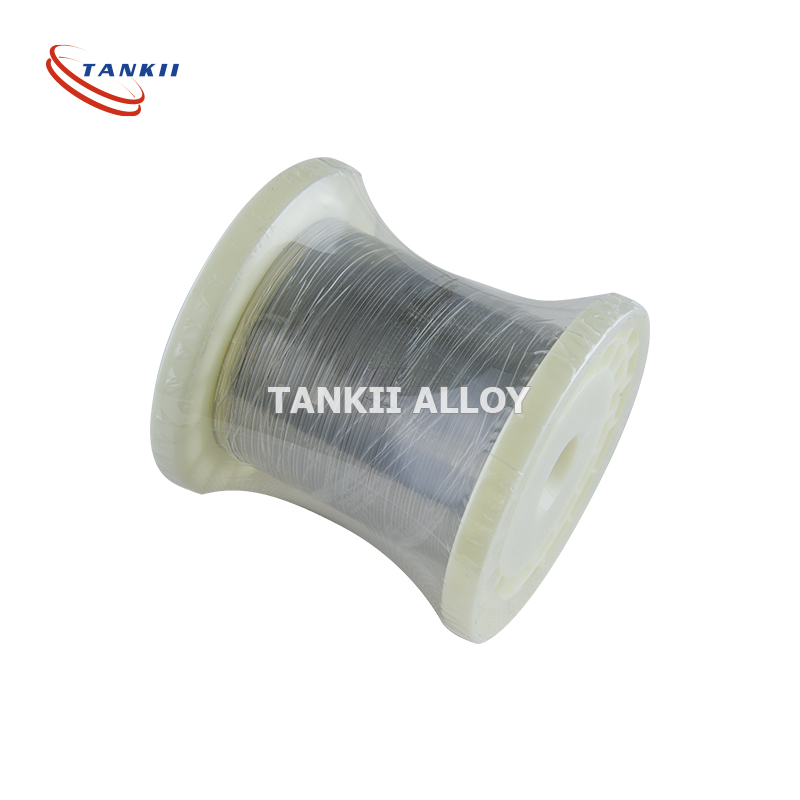

Lithapo tsa motsoako oa Fe-Cr-Al li entsoe ka li-alloy tsa tšepe tsa chromium aluminium tse nang le likarolo tse nyane tse arabelang tse kang yttrium le zirconium 'me li hlahisoa ka ho qhibilihisa, ho rola tšepe, ho betla, ho annealing, ho hula, kalafo ea bokaholimo, teko ea taolo ea khanyetso, jj.

Terata ea Fe-Cr-Al e bōpiloe ka mochini o pholileng o iketsang ka lebelo le phahameng oo matla a oona a laoloang ke khomphutha, li fumaneha e le terata le ribone (strip).

Likarolo le melemo

1. Mocheso o phahameng o sebelisoang, mocheso o phahameng o sebelisoang o ka fihla ho 1400C (0Cr21A16Nb, 0Cr27A17Mo2, jj.)

2. Khokahano ea mocheso o tlase oa khanyetso

3. Koefficient e tlase ea katoloso ea mocheso ho feta li-super-alloy tsa Ni-base.

4. Ho hanyetsa motlakase haholo

5. Khanyetso e ntle ea ts'enyeho tlas'a mocheso o phahameng, haholo-holo tlas'a sepakapaka se nang le li-sulfide

6. Mojaro o phahameng oa bokaholimo

7. E hanela ho thekesela

8. Litšenyehelo tse tlase tsa thepa e tala, Bongata bo tlase le theko e tlase ha li bapisoa le terata ea Nichrome.

9. Khanyetso e phahameng ea oxidation ho 800-1300ºC

10. Bophelo bo bolelele ba tšebeletso

Ho thehoa ha mekhahlelo ea alumina e tsitsitseng ka lebaka la oxidation ea khoeboMotsoako oa FeCrAlLithapo (botenya ba 0.5 mm) lithempereichara tse fapaneng le linako li se li hlahlobiloe. Lisampole li ile tsa oxidised ka isothermally moeeng ho sebelisoa thermogravimetric analyzer (TGA). Sebopeho sa lisampole tse oxidised se ile sa hlahlojoa ho sebelisoa Electronic Scanning Electron Microscope (ESEM) 'me X-ray holim'a tlhahlobo ea bokaholimo e entsoe ho sebelisoa Energy Dispersive X-Ray (EDX). Mokhoa oa X-Ray Diffraction (XRD) o sebelisitsoe ho hlalosa mohato oa kholo ea oxide. Phuputso eohle e bontšitse hore ho ne ho khoneha ho holisa gamma alumina ea sebaka se phahameng holim'aMotsoako oa FeCrAlbokaholimo ba terata ha bo oxidised ka tsela e sa fetoheng mochesong ka holimo ho 800°C ka lihora tse 'maloa.

| Aluminium ea Tšepe Chrome | |||||||

| OCr25Al5 | CrAl25-5 | 23.0 | 71.0 | 6.0 | |||

| OCr20Al5 | CrAl20-5 | 20.0 | 75.0 | 5.0 | |||

| OCr27Al7Mo2 | 27.0 | 65.0 | 0.5 | 7.0 | 0.5 | ||

| OCr21Al6Nb | 21.0 | 72.0 | 0.5 | 6.0 | 0.5 | ||

| Aluminium ea Tšepe Chrome | ||

| OCr25Al5 | E ka sebelisoa maemong a ts'ebetso ho fihlela ho 1350°C, leha e ka senyeha. | Lintho tse futhumatsang tsa lionto tse nang le mocheso o phahameng le li-heater tse khanyang. |

| OCr20Al5 | Motsoako oa ferromagnetic o ka sebelisoang mochesong o fihlang ho 1300°C. O lokela ho sebelisoa tikolohong e omileng ho qoba ho bola. O ka senyeha mochesong o phahameng. | Lintho tse futhumatsang tsa lionto tse nang le mocheso o phahameng le li-heater tse khanyang. |

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo