Rea u amohela liwebsaeteng tsa rona!

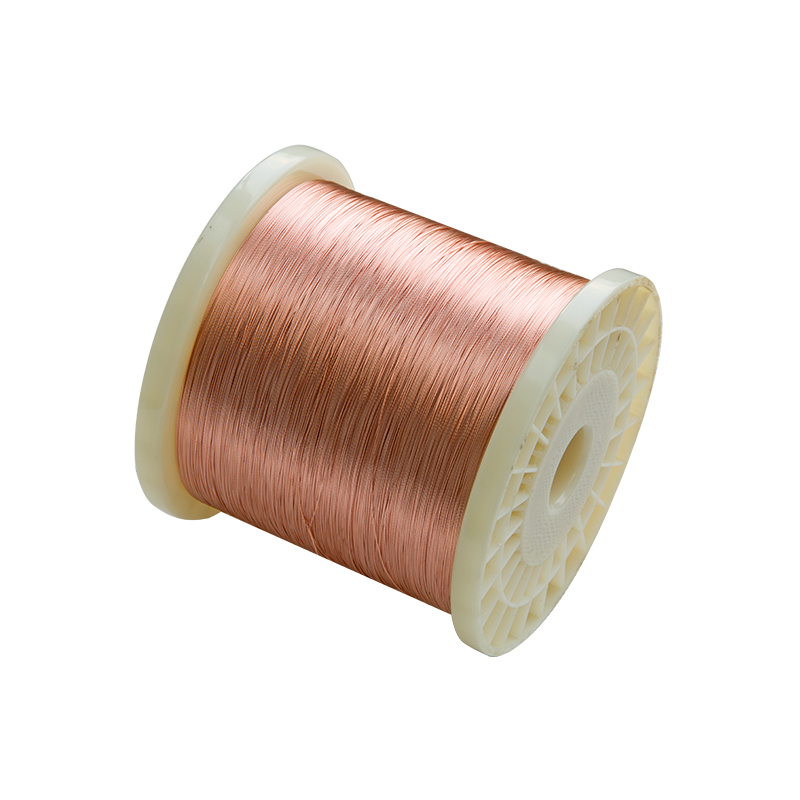

Terata ea Koporo e Koahetsoeng ka Tinkii ea Tankii ea 1.0mm T2 Koporo e Khubelu e Thibelang ho Kena ha Okisi le Tsamaiso e Hlollang ea Motlakase

Tlhaloso ea Sehlahisoa

Terata ea Koporo e Koahetsoeng ka Mathining ea 1.0mm (Kopo e Khubelu e Hloekileng, Sekoahelo sa Tin sa 3-5μ)

Kakaretso ea Sehlahisoa

Jwalo ka mokhanni wa motlakase o tshepahalang haholo ho tswa ho Tankii Alloy Material,Terata ea koporo e entsoeng ka makotikoti ea 1.0mme kopanya melemo e 'meli ea mantlha: ho khanna ha koporo e khubelu e hloekileng haholo (sehlopha sa T2) le tšireletso ea ho thibela ho bola ha sekoahelo sa tin se nepahetseng sa 3-5μ. E entsoe ka mokhoa o tsoetseng pele oa Huona oa ho kenya tin ka ho chesa o tsoelang pele—o nang le tlhokomelo ea botenya ba nako ea sebele le taolo ea mocheso—terata e etsa bonnete ba hore lera la tin le khomarela ka ho lekana khubung ea koporo e tiileng ea 1.0mm, ha ho na masoba kapa matheba a masesaane. E rarolla lintlha tse peli tsa bohlokoa tsa bohloko ba terata ea koporo e se nang letho: ho fokotseha ha ho khanna ha tin ho bakoang ke oxidation le ho se khone ho solder hantle, e leng se etsang hore e be ntho ea bohlokoa bakeng sa likhokahano tsa motlakase tse hlokang botsitso ba nako e telele, kopano e bonolo, le ho hanyetsa libaka tse mongobo/tsa indasteri.

Litifikeiti tse Tloaelehileng le tse Bohlokwa

- Kereiti ea mokhanni: Koporo e khubelu e hloekileng ea T2 (e latela GB/T 3956-2008; e lekanang le ASTM B33, IEC 60288 Sehlopha sa 1)

- Tekanyetso ea ho Koahela Tin: GB/T 4910-2009, IEC 60317-2 (ha e na loto: Pb ≤0.005%, Sn ≥99.9%)

- Litifikeiti tsa Boleng: E latela melao ea RoHS 2.0, sistimi ea taolo ea boleng ba ISO 9001, tumello ea liteko tsa tikoloho tsa SGS

- Moetsi: Tankii Alloy Material (lilemo tse 15+ tsa boiphihlelo ba ho sebetsana le koporo copper conductor)

Melemo ea Tshebetso ea Motheo

1. Mokhanni oa Koporo e Khubelu e Hloekileng: Mokhanni o sa Bapisoeng oa Koporo

- Ho Tsamaisa Motlakase: ≥98% IACS (20℃), e feta koporo e kopantsoeng haholo (mohlala, li-alloy tsa CuNi: ~20% IACS) le aluminium (61% IACS). E netefatsa ho theoha ho fokolang ha motlakase lipotolohong tse nang le motlakase o tlase (mohlala, terata ea likoloi ea 12V, likhoele tsa USB tsa 5V) le phetiso e potlakileng ea lets'oao bakeng sa li-sensor.

- Bokgoni ba Mekaniki: Ho lelefatsa ≥30% (25℃) le matla a ho thapolla ≥200 MPa. E ka mamella ho kobeha ho pheta-phetoang (teko ea ho kobeha ea 180° ≥makhetlo a 10 ntle le ho robeha) bakeng sa ho kenya lithapo libakeng tse thata (mohlala, likarolo tsa kahare tsa sesebelisoa, likhokahano tsa moeli oa PCB).

2. 3-5μ Sekoahelo sa Tin se Nepahetseng: Tšireletso e Lebisitsoeng

- Thibelo ea ho Thibela ho Kena ha Oxidation: Lera le teteaneng la tin le thibela moea/mongobo ho kopana le koporo, e leng se thibelang ho thehwa ha oxide ya koporo e tsamaisang motlakase (CuO/Cu₂O). Esita le mongobong wa 80% ka dikgwedi tse 12, terata e boloka ≥97% ya motlakase wa pele (ha ho bapiswa le koporo e se nang letho: e theohela ho 85% ka dikgwedi tse 3).

- Ho Thekisoa ho Ntlafalitsoeng: Sebaka se tlase sa ho qhibiliha ha Tin (232℃) se nolofalletsa "ho kolobisa hang-hang" nakong ea ho kopanya - ha ho hlokahale ho hloekisa pele kapa ho kenya tšebetsong ha flux. E fokotsa nako ea kopano ea PCB ka 40% khahlano le koporo e se nang letho (e hlokang ho tlosoa ha oxide ka ho e sanda/lik'hemik'hale).

- Moralo oa Botenya bo Leka-lekaneng: Botenya ba 3-5μ bo qoba maemo a mabeli a feteletseng: masela a masesaane (<3μ) a ke ke a koahela liphoso tsa koporo, ha masela a masesaane (>5μ) a etsa hore terata e pshatlehe habonolo (e sekamele ho petsoha nakong ea ho kobeha).

Litlhaloso tsa Tekheniki

| Paramethara | Boleng bo qaqileng |

| Bophara ba Lebitso (Kakaretso) | 1.0mm (mokhanni: ~0.992-0.994mm; sekoahelo sa thini: 3-5μ) |

| Mamello ea bophara | ± 0.02mm |

| Botenya ba ho Koahela Tin | 3μ (bonyane) – 5μ (boholo); ho lekana ha botenya: ≥95% (ha ho na letheba <2.5μ) |

| Ho Tsamaisa Motlakase (20℃) | ≥98% IACS |

| Matla a tšepe | 200-250 MPa |

| Ho Lelefatsa Nako ea Phomolo | ≥30% (L0=200mm) |

| Ho khomarela Tin | Ha ho na ho petsoha/ho petsoha ka mora ho kobeha ka 180° (radius=5mm) + teko ya theipi (theipi ya 3M 610, ha ho na masalla a thini) |

| Khanyetso ea ts'enyeho | E feta teko ea spray ea letsoai ea ASTM B117 (lihora tse 48, 5% NaCl, 35℃) - ha e na mafome a mafubelu, e na le matheba a thini |

| Mefuta ea Mocheso o Buuoang | -40℃ (tenyetseho e tlase mochesong, ha ho petsohe) ho isa ho 105℃ (tšebeliso e tsoelang pele, ha ho na ho qhibiliha ha thini) |

Phepelo ea Sehlahisoa le ho se Etsa ka Tsela e Ikhethileng

| Ntho | Tlhaloso |

| Foromo ea Phepelo | Mokhanni o tiileng (o tloaelehileng); mokhanni o tsielehileng (o etselitsoeng: 7/0.43mm, 19/0.26mm) |

| Tlhophiso ea Spool | 500m/1000m ka spool (thepa ea spool: polasetiki ea ABS, bophara: 200mm, lesoba la mantlha: 50mm) |

| Qetello ea Bokaholimo | Lekotikoti le khanyang (kamehla); lekotikoti le sa hlakang (le ikgethileng, bakeng sa ditshebediso tse thibelang kganya) |

| Mekhoa e Eketsehileng ea Kalafo | Ho kenya mocheso ka boikhethelo (PVC/XLPE/Silicone, botenya: 0.1-0.3mm, 'mala: o motsho/o mofubedu/o moputsoa) |

| Sephutheloana | Mokotlana oa foile ea aluminium o koetsoeng ka vacuum cleaner (o sa keneleng mongobo) + lebokose la kantle (le nang le desiccant, le thibelang tšusumetso) |

Maemo a Tloaelehileng a Kopo

- Lisebelisoa tsa Ntlo: Lithapo tsa kahare bakeng sa mechini e hlatsoang (e hanelang mongobo), lihatsetsi (e tenyetsehang mochesong o tlase), le lionto tsa microwave (e hanelang mocheso ho fihlela ho 105℃).

- Lisebelisoa tsa Elektroniki tsa Likoloi: Li-terminal tsa sehokelo bakeng sa libeteri tsa koloi (thibela ho bola), terata ea sensor (letšoao le tsitsitseng), le litsamaiso tsa infotainment ka koloing (ho theoha ha motlakase o tlase).

- PCB le Lisebelisoa tsa Elektroniki tsa Bareki: Ho kopanya ka masoba a lesoba bakeng sa diboto tsa Arduino/Raspberry Pi, di-conductor tsa thapo ya USB-C, le terata ya LED strip (ho e kopanya habonolo).

- Taolo ea Indasteri: Lithapo tsa terata bakeng sa liphanele tsa PLC (ho hanyetsa mongobo oa indasteri) le lisebelisoa tsa motlakase tse nang le motlakase o tlase (tahlehelo e fokolang ea matla).

- Lisebelisoa tsa Bongaka: Lithapo tsa kahare bakeng sa lisebelisoa tsa tlhahlobo tse nkehang habobebe (ha li na loto, li latela maemo a biocompatibility) le lipompo tse nyane tsa bongaka (tse kobehang habonolo).

Netefatso ea Boleng ho tsoa ho Tankii Alloy Material

Sehlopha se seng le se seng sa terata ea koporo e entsoeng ka makotikoti ea 1.0mm se hlahlojoa ka makhetlo a mararo a bohlokoa:

- Teko ea Botenya ba Tin: Sesefatsi sa X-ray fluorescence (XRF) (ho nepahala: ± 0.1μ) – lintlha tse 5 tsa ho nka disampole ka spool.

- Teko ea ho khanna: Mohlahlobi oa probe ea lintlha tse 'ne (ho nepahala: ± 0.5% IACS) – disampole tse 3 ka sehlopha.

- Teko ea Mechini: Mochini oa tlhahlobo oa bokahohle (ho tenyetseha/ho lelefatsa) + teko ea ho kobeha (ho khomarela) – disampole tse 2 ka sehlopha.

Disampole tsa mahala (bolelele ba 1m, dikotwana tse 2-3 ka tlhaloso) le Ditlaleho tse qaqileng tsa Teko ya Thepa (MTR) di a fumaneha ha di kopuwa. Sehlopha sa rona sa botekgeniki se fana ka tshehetso ya motho ka mong bakeng sa ditlhoko tse ikgethileng (mohlala, kgetho ya thepa ya ho kenya mocheso bakeng sa ditshebediso tsa mocheso o phahameng, moralo wa khomphutha e lahlehileng bakeng sa terata e tenyetsehang).

Ngola molaetsa oa hau mona 'me u o romelle ho rona

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo