Rea u amohela liwebsaeteng tsa rona!

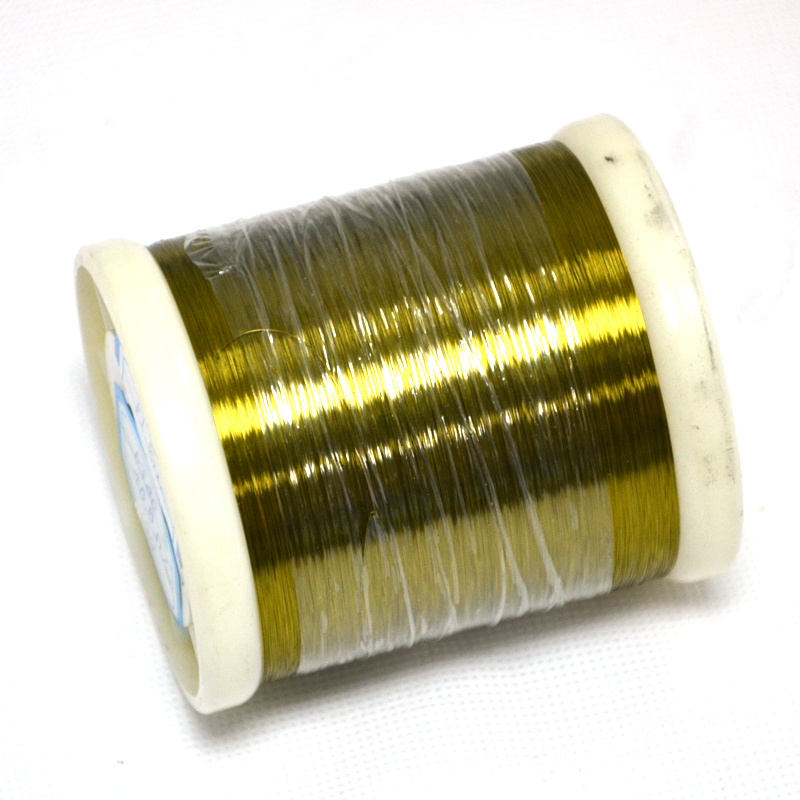

Terata e nang le enamel ea Tankii Polyester CuNi40 Alloy e nang le mocheso o phahameng

Tlhōrō ea Insulation:

1) Terata ea ho hanyetsa polyester, sehlopha sa 130

2) Terata e fetotsoeng ea ho hanyetsa polyester, sehlopha sa 155

3) Terata ea ho hanyetsa polyesterimide, sehlopha sa 180

4) Polyester (imide) e koahetsoeng ka terata ea ho hanyetsa polyamide-imide, sehlopha sa 200

5) Terata ea ho hanyetsa Polyimide, sehlopha sa 220

| Constantan 6J40 | Constantan e Ncha | Manganin | Manganin | Manganin | ||

| 6J11 | 6J12 | 6J8 | 6J13 | |||

| Li-elemente tse ka Sehloohong tsa Lik'hemik'hale % | Mn | 1~2 | 10.5~12.5 | 11~13 | 8~10 | 11~13 |

| Ni | 39~41 | - | 2~3 | - | 2~5 | |

| Cu | PHOMOLLO | PHOMOLLO | PHOMOLLO | PHOMOLLO | PHOMOLLO | |

| Al2.5~4.5 Fe1.0~1.6 | Si1~2 | |||||

| Mefuta ea Mocheso bakeng sa Likaroloana | 5~500 | 5~500 | 5~45 | 10~80 | 10~80 | |

| Botenya | 8.88 | 8 | 8.44 | 8.7 | 8.4 | |

| g/cm3 | ||||||

| Ho hanyetsa | 0.48 | 0.49 | 0.47 | 0.35 | 0.44 | |

| μΩ.m,20 | ± 0.03 | ± 0.03 | ± 0.03 | ± 0.05 | ± 0.04 | |

| Katoloso | ≥15 | ≥15 | ≥15 | ≥15 | ≥15 | |

| %Φ0.5 | ||||||

| Khanyetso | -40~+40 | -80~+80 | -3~+20 | -5~+10 | 0~+40 | |

| Thempereichara | ||||||

| Khoutu | ||||||

| α,10 -6 / | ||||||

| Thermoelectromotive | 45 | 2 | 1 | 2 | 2 | |

| qobella ho ea Koporong | ||||||

| μv/(0~100) | ||||||

Tpye ea terata e se nang letho

| thepa e ka sehloohong mofuta | Cuni1 | CuNI2 | CuNI6 | CuNI10 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNI44 | |

| k'hemik'hale e ka sehloohong sebopeho | Ni | 1 | 2 | 6 | 10 | 19 | 23 | 30 | 34 | 44 |

| MN | / | / | / | / | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| CU | phomolo | phomolo | phomolo | phomolo | phomolo | phomolo | phomolo | phomolo | phomolo | |

| ho sebetsa ka thata mocheso | / | 200 | 220 | 250 | 300 | 300 | 350 | 350 | 400 | |

| densityg/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| ho hanyetsa ka 20 °c | 0.03 ± 10% | 0.05 ± 10% | 0.1 ± 10% | 0.15 ± 10% | 0.25 ± 5% | 0.3 ± 5% | 0.35 ± 5% | 0.40 ± 5% | 0.49 ± 5% | |

| tekanyo ea mocheso ea khanyetso | <100 | <120 | <60 | <50 | <25 | <16 | <10 | -0 | <-6 | |

| matla a ho thapolla mpa | >210 | >220 | >250 | >290 | >340 | >350 | >400 | >400 | >420 | |

| ho lelefatsa | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | |

| ntlha ea ho qhibiliha °c | 1085 | 1090 | 1095 | 1100 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| coefficient ea conductivity | 145 | 130 | 92 | 59 | 38 | 33 | 27 | 25 | 23 |

Ngola molaetsa oa hau mona 'me u o romelle ho rona

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo