Rea u amohela liwebsaete tsa rona!

4J52 / Pernifer 50 khalase e tiisa li-tube 52 alloy logo

Boholo ba boholo:

* Sheet-Komm-0.1mm ~ 40MM, bophara: ≤300mm, bophara: Ho chesa), bo khanyang

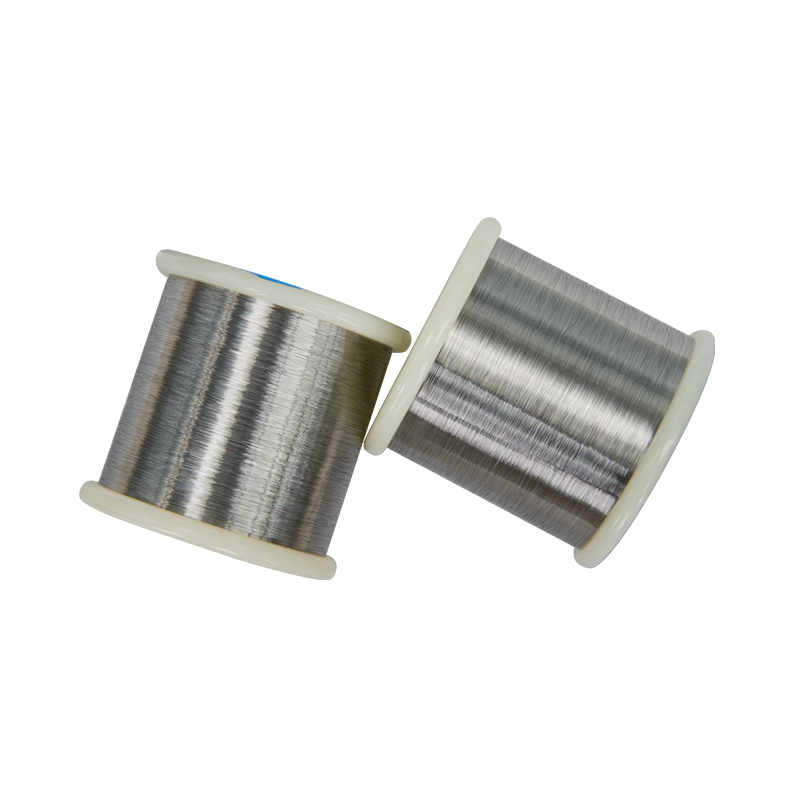

* Wire Round-Da 0.1mm ~ - Boemo

* Terata e sephara-Da 0.5mm ~ da 5.0, bolelele: ≤1000mm

* Bar-Da 5.0mm ~ - bolelele: ≤2000mm

Dia 8.0MM ~ Dia 32.0MM

DA 32.0MM ~ - - bolelele: ≤1300mm, maemo: ho chesa, ho chesa, ho chesa, ho chesa, ho chesa

* Capillary-O 3mmm ~ 1.0mm, id 0.1mm ~ 8.0mm ~ 8.0M

* Phala-O 120mm ~ 8.0mm ea 3.0mm ~ 129mm.

Chemistry:

| Cr | Al | C | Fe | Mn | Si | P | S | Ni | Mg | |

| Min | - | - | - | - | - | - | - | - | 50.5 | - |

| Max | 0.25 | 0.10 | 0.05 | Bal. | 0.60 | 0.30 | 0.025 | 0.025 | - | 0.5 |

Karolelano ea Terata ea Kakaretso ea Linear Liner:

| Keletso | α1 / 10-6ºC-1 | |||||||

| 20 ~ 100,5 | 20 ~ 200ºC | 20 ~ 300ºC | 20 ~ 350ºC | 20 ~ 400ºC | 20 ~ 450ºO | 60, 500ºC | 20 ~ 600ºC | |

| 4J52 | 10.3 | 10.4 | 10.2 | 10.3 | 10.3 | 10.3 | 10.3 | 10.8 |

LITLHAKISO:

| Boemo | Approx. matla a tšepe | Approx. mocheso o sebetsang | ||

| N / mm² | KSI | ° C | ° F | |

| E pakiloe | 450 - 550 | 65 - 80 | ho fihlela +450 | ho fihlela +840 |

| Ho huleloa ka thata | 700 - 900 | 102 - 131 | ho fihlela +450 | ho fihlela +840 |

| Ho theha: |

| Lello le na le pheko e ntle ebile e ka thehoa ka mokhoa o tloaelehileng. |

| Welding: |

| Wealding ka mekhoa e tloaelehileng e loketse leoto la sena. |

| Phekolo ea mocheso: |

| Alloy 52 e lokela ho phatlalatsoa ka 1500F e lateloe ke moea. Ho imolla khatello ea likhoka ho ka etsoa ho 1000f. |

| Force: |

| Ho lila ho lokela ho etsoa ka mocheso oa 2150 f. |

| Ho bata |

| Alloy e bata haholo. Mohato o tebileng o tebileng o lokela ho hlalosoa bakeng sa ts'ebetso eo e etsang ts'ebetso le sehlopha se patiloeng bakeng sa ho theha. |

Ngola molaetsa oa hau mona 'me u e romelle ho rona