Koporo nikele motsoako terata

Tlhaloso ea Sehlahisoa

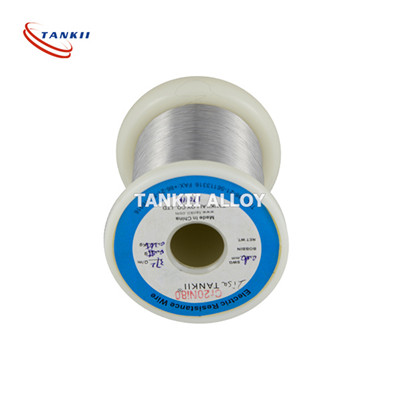

Li-alloy tsa koporo tsa nikeli (CuNi) ke thepa e mahareng ho isa tlase e hanyetsanang hangata e sebelisoang lits'ebetsong tse nang le mocheso o phahameng ka ho fetisisa oa ts'ebetso ho fihlela ho 400°C (750°F).

Ka di-coefficient tse tlase tsa mocheso tsa ho hanyetsa motlakase, ho hanyetsa, mme ka hona tshebetso, ho tsitsitse ho sa tsotelehe mocheso. Di-alloy tsa koporo tsa nickel di ithorisa ka ho ductility e ntle ka mechini, di a kopanngwa habonolo le ho kopanngwa, mme di na le ho hanyetsa ho ts'oha ho hoholo. Di-alloy tsena hangata di sebediswa ditshebedisong tse phahameng tsa motlakase tse hlokang boemo bo hodimo ba ho nepahala.

Resistivity ea terata ea alloy e hanyetsang mocheso ea koporo e tlase, e na le khanyetso e ntle ea mafome, thepa ea ho tjheseletsa le thepa e ka sebelisoang mochining, e loketse ho sebelisoa ha relay ea overload ea mocheso, li-circuit breaker tsa motlakase o tlase, le lisebelisoa tse ling tsa motlakase tse nang le motlakase o tlase le lisebelisoa tsa ntlo le lisebelisoa tse ling tsa motlakase tse etsang karolo ea ho futhumatsa, 'me ke thepa ea bohlokoa tlhahisong ea cable ea ho futhumatsa.

| Khoutu | Ho hanyetsa | Bohale ba ho Sebetsa | Mocheso oa Coeffi. oa Khanyetso | EMF Khahlanong le Koporo (0~100℃) | Sebopeho sa Lik'hemik'hale (%) | Mekaniki, Thepa | |||||

| Mn | Ni | Cu | Matla a ho Tenyetseha (N/mm2) | Ho lelefatsa % (Ka tlase ho) | |||||||

| Bophara <=1.0mm | Bophara ba > = 1.0mm | ||||||||||

| NC003 | CuNi1 | 0.03 | 200 | 100 | -8 | - | 1 | Phomolo | 210 | 18 | 25 |

| NC005 | CuNi2 | 0.05 | 200 | 120 | -12 | - | 2 | Phomolo | 220 | 18 | 25 |

| NC010 | CuNi6 | 0.10 | 220 | 60 | -18 | - | 6 | Phomolo | 250 | 18 | 25 |

| NC012 | CuNi8 | 0.12 | 250 | 57 | -22 | - | 8 | Phomolo | 270 | 18 | 25 |

| NC015 | CuNi10 | 0.15 | 250 | 50 | -25 | - | 10 | Phomolo | 290 | 20 | 25 |

| NC020 | CuNi14 | 0.20 | 250 | 38 | -28 | 0.3 | 14.2 | Phomolo | 310 | 20 | 25 |

| NC025 | CuNi19 | 0.25 | 300 | 25 | -32 | 0.5 | 19 | Phomolo | 340 | 20 | 25 |

| NC030 | CuNi23 | 0.30 | 300 | 16 | -34 | 0.5 | 23 | Phomolo | 350 | 20 | 25 |

| NC035 | CuNi30 | 0.35 | 300 | 10 | -37 | 1.0 | 30 | Phomolo | 400 | 20 | 25 |

| NC040 | CuNi34 | 0.40 | 350 | 0 | -39 | 1.0 | 34 | Phomolo | 400 | 20 | 25 |

| NC050 | CuNi44 | 0.50 | 400 | 1-6 | -43 | 1.0 | 34 | Phomolo | 420 | 20 | 25 |

| Motsoako | DN - Lebitso la Khoebo | Tjhe ea thepa. | Nomoro ea UNS | Tlhaloso ea ASTM | Tlhaloso ea DIN |

| CuNi1 | CuNi1 | ||||

| CuNi2 | CuNi2 | 2.0802 | C70200 | ASTM B267 | DIN 17471 |

| CuNi6 | CuNi6 | 2.0807 | C70500 | ASTM B267 | DIN 17471 |

| CuNi10 | CuNi10 | 2.0811 | C70700 | ASTM B267 | DIN 17471 |

| CuNi10Fe1Mn | CuNi10Fe1Mn | (2.0872) / (CW352H) | C70600 | ASTM B151 | |

| CuNi15 | CuNi15 | ||||

| CuNi23Mn | CuNi23Mn | 2.0881 | C71100 | ASTM B267 | DIN 17471 |

| CuNi30Mn | CuNi30Mn | 2.0890 | |||

| CuNi30Mn1Fe | CuNi30Mn1Fe | (2.0882) / (CW354H) | C71500 | ASTM B151 | |

| CuNi44Mn1 | Vernicon | 2.0842 | DIN 17471 |

294: Lebitso le Tloaelehileng:

Alloy294, Cuprothal294, Nico, MWS-294, Cupron, Copel, Alloy45, Cu-Ni102, Cu-Ni44, Cuprothal, Cupron, Copel, Neutrology, Advance, Konstantan

A30: Lebitso le Tloaelehileng:

Alloy 30, MWS-30, Cuprothal 5, Cu-Ni 23, Alloy 260, Cuprothal 30 HAI-30, Cu-Ni2, Alloy 230, Nickel Alloy 30

A90: Lebitso le Tloaelehileng:

Motsoako oa 95, 90 Motsoako oa aluminium, MWS-90, Cu-Ni 10, Cuprothal 15, Cu-Ni 10, Motsoako oa aluminium 320 Motsoako oa aluminium 90, Motsoako oa aluminium 290, #95 Motsoako oa aluminium, Cuprothal 90, HAI-90, Motsoako oa aluminium 260, Motsoako oa aluminium 90

A180: Lebitso le Tloaelehileng:

Motsoako oa 180, 180 Motsoako oa 180, MWS-180, Cuprothal 30, Midohm, Cu-Ni 23, Motsoako oa Nickel 180

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo