Terata ea motsoako oa chrome ea nikeli Ni70Cr30

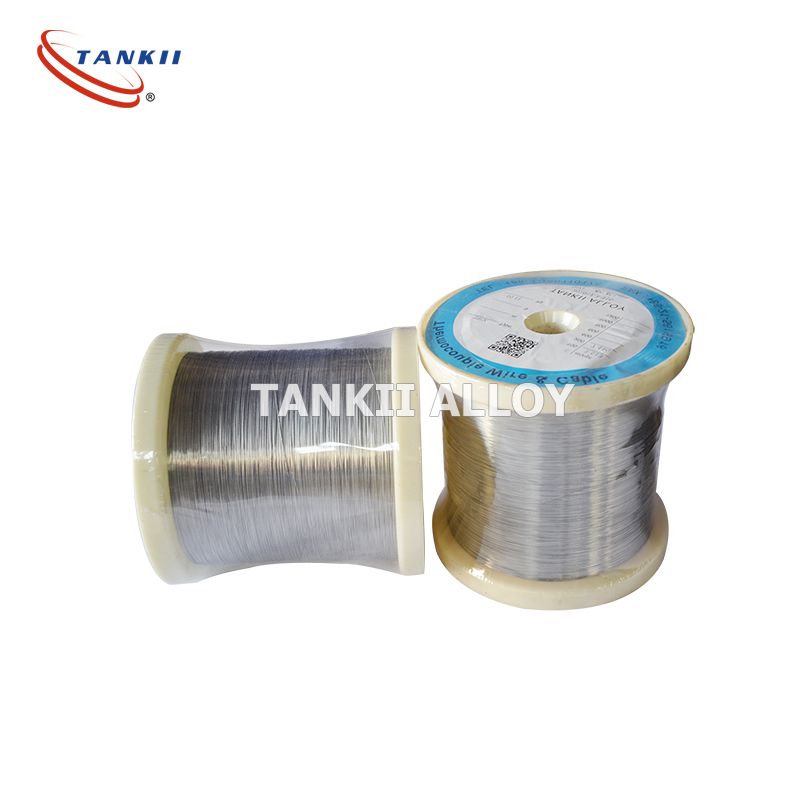

Terata ea motsoako oa chrome ea nikeliNi70Cr30

Cr30Ni70 Nichrome Alloy Eletrothermal Coil Strip, Khanyetso ea Sable bakeng sa Element ea ho Futhumatsa,

NiCr70/30

Motsoako oa chromium oa nikeli o nang le khanyetso ea tšepe ea motlakase o phahameng, 'mele o ka holimo o hokahane hantle. Mochesong o phahameng le matla a phahameng,

le ts'ebetso e ntle le ts'ebetso e ka sebelisoa haholo ho tjheseletsa metsoako ea tšepe, ea motlakase, ea mechini le ea motlakase.

liindasteri tsa tlhahiso bakeng sa ho etsa thepa e thibelang mocheso.

Mofuta oa NiCr: Cr20Ni80, Cr15Ni60, Cr20Ni35, Cr20Ni30, Cr25Ni20 jj. Lebanta la motlakase le bataletseng la letoto, terata ea mollo ea motlakase.

3. Boholo ba sehlahisoa:

Botenya: 0.02—-4.0mm

Bophara: 2.5—-250mm

Tekanyetso: GB1234-95

Bokaholimo bo khanyang le bo boreleli

Ni70Cr30

Dikahare tsa Khemikhale, %

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Tse ling |

| Boholo | |||||||||

| 0.08 | 0.02 | 0.015 | 0.60 | 0.75~1.60 | 28.0~31.0 | Bala. | Boholo 0.50 | Boholo 1.0 | - |

![]()

![]()

![]()

![]()

Matlotlo a Mekaniki

| Mocheso o Phahameng oa Tšebeletso e Tsoelang Pele: Ho kgutlela morao (20ºC)/Ω·m::Botebo: Ho tsamaisa mocheso: Katoloso ea Thermal Coefficient: Sebaka sa ho Qhibiliha: Ho lelefatsa: Sebopeho sa Micrographic: Thepa ea Magnetic: | 1250ºC 1.18 +/-0.05 (Sekgahla: <0.5mm) 1.20+/-0.05 (Dia: ≥0.50 mm) 8.1 g/cm3 45.2 KJ/m·h·ºC 17×10-6/ºC (20ºC~1000ºC) 1380ºC Bonyane 20% Austenite e seng ea makenete |

![]()

![]()

![]()

![]()

| Mofuta | Cr20Ni80 | Cr15Ni60 | Cr30Ni70 | Cr20Ni35 | Cr20Ni30 | |

| Sebopeho sa lik'hemik'hale tse ka sehloohong | Ni | Phomolo | 55.0~61.0 | Phomolo | 34.0~37.0 | 30.0~34.0 |

| Cr | 20.0~23.0 | 15.0~18.0 | 28.0~31.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1 | Phomolo | ≤1 | Phomolo | Phomolo | |

| Mocheso o Phahameng (ºC) | 1200 | 1150 | 1250 | 1100 | 1100 | |

| Khanyetso ea ho lokisa mocheso. (CT) | 1.09±0.05 | 1.11±0.05 | 1.18±0.05 | 1.04±0.05 | 1.06±0.05 | |

| Sebaka sa ho qhibiliha (ºC) | 1400 | 1390 | 1380 | 1390 | 1390 | |

| Resistivityρ20ºC(10-6Ω.m) | 800ºC | 1.008 | 1.078 | 1.028 | 1.188 | 1.173 |

| 1000ºC | 1.014 | 1.095 | 1.033 | 1.219 | 1.201 | |

| 1200ºC | 1.025 | 1.043 | ||||

| Boleng ba bophelo bo potlakileng | Tem.(ºC) | 1175 | 1100 | 1200 | 1050 | 1050 |

| hora(h) | ≥110 | ≥100 | ≥110 | ≥100 | ≥100 | |

| Matla a khoheli a itseng (g/cm3) | 8.40 | 8.2 | 8.1 | 7.90 | 7.90 | |

| Ho lelefatsa(%) | ≥25 | ≥25 | ≥20 | ≥20 | ≥20 | |

| Mocheso (kj/mhºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Mocheso o itseng (20ºC)j/g.ºC | 0.440 | 0.494 | 0.461 | 0.500 | 0.500 | |

| Eketsa matla (20~1000ºC)α*10-6ºC | 18.0 | 17.0 | 17.1 | 19.0 | 19.0 | |

| Matla a ho tenyetseha (kg/mm2) | >85 | >85 | >85 | >85 | >85 | |

| Ho kobeha khafetsa (F/R) | >12 | >12 | >12 | >12 | >12 | |

| Sebopeho se senyenyane | Austenitic | Austenitic | Austenitic | Austenitic | Austenitic | |

![]()

![]()

![]()

![]()

Lihlopha tsa lihlahisoa

-

Mohala

-

Imeile

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Holimo