Nickel chrome alloy terata Ni70Cr30

Mohala oa motsoako oa Nickel chromeNi70Cr30

Cr30Ni70 Nichrome Alloy Eletrothermal Coil Strip, Sable Resistance For Heating Element,

NiCr70/30

Nickel chromium alloy e nang le iron resistance electrothermal high resistivity, bokaholimo ba 'mele hantle.Ka mocheso o phahameng le matla a phahameng,

le tshebetso e ntle le ho sebetsa e ka 'na tjheseletsa tlhaho ho pharaletseng sebelisoa metallurgical, motlakase, metsoako ea mechine le motlakase

liindasteri tsa ho etsa thepa e thibelang mocheso.

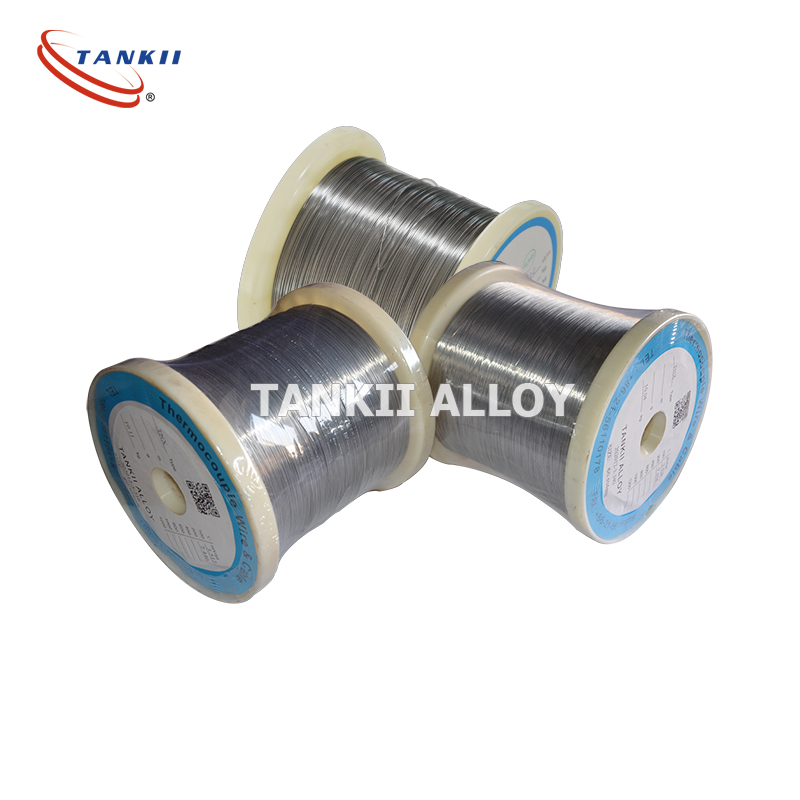

Mofuta oa NiCr:Cr20Ni80,Cr15Ni60, Cr20Ni35, Cr20Ni30, Cr25Ni20 joalo-joalo.Series lebanta le bataletseng la motlakase, terata ea mollo ea motlakase.

3.Sehlahisoa sa boholo:

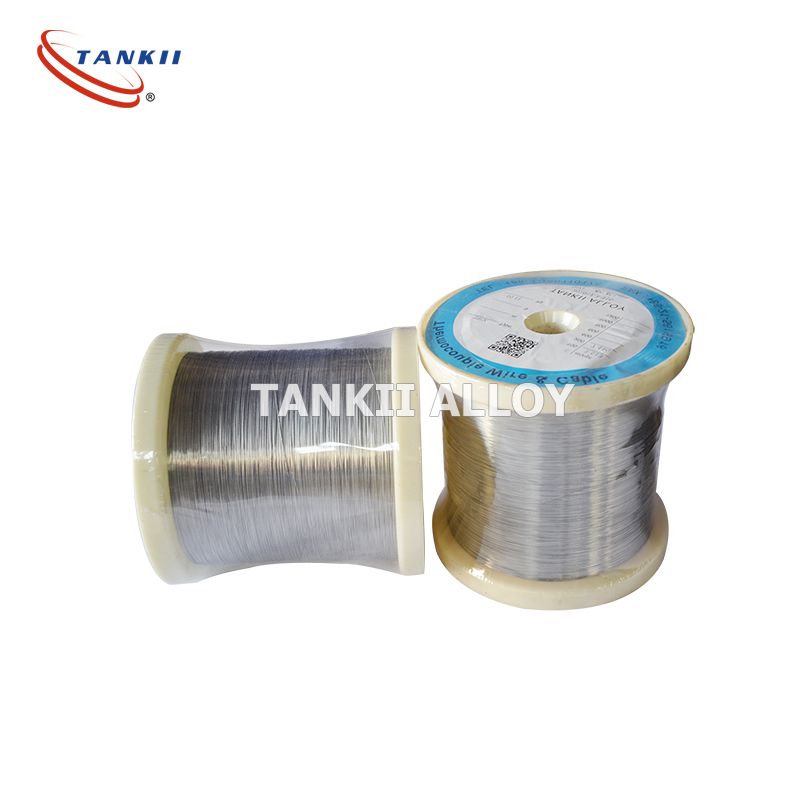

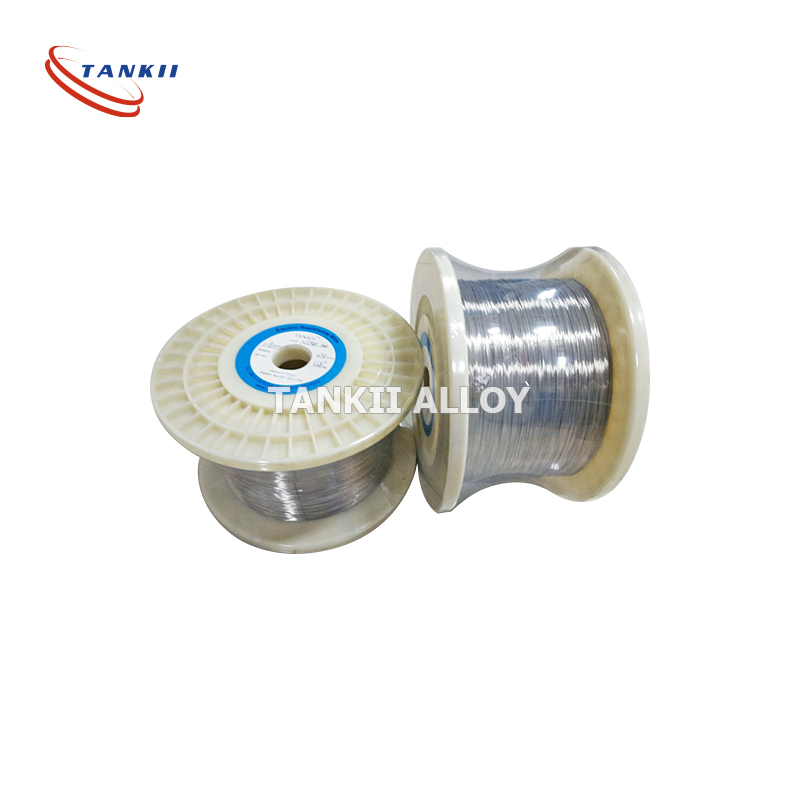

Botenya: 0.02—-4.0mm

Bophara: 2.5—-250mm

Boemo:GB1234-95

Sebaka se khanyang le se Boreleli

Ni70Cr30

Litaba tsa Lik'hemik'hale, %

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Tse ding |

| Max | |||||||||

| 0.08 | 0.02 | 0.015 | 0.60 | 0.75 ~ 1.60 | 28.0~31.0 | Bal. | Boholo ba 0.50 | Boholo ba 1.0 | - |

Thepa ea Mechini

| Thempereichara e Tsoelang Pele ea Tšebeletso: Resisivity ( 20ºC)/Ω·m::Density: Thermal Conductivity: Coefficient ea Katoloso ea Thermal: Melting Point: Elongation: Sebopeho sa Micrographic: Thepa ea Magnetic: | 1250ºC 1.18 +/-0.05 (Dia: <0.5mm) 1.20+/-0.05 (Dia: ≥0.50 mm) 8.1 g/cm3 45.2 KJ/m·h·ºC 17×10-6/ºC (20ºC~1000ºC) 1380ºC Ka tlase ho 20% Austenite nonmagnetic |

| Mofuta | Cr20Ni80 | Cr15Ni60 | Cr30Ni70 | Cr20Ni35 | Cr20Ni30 | |

| Sebopeho sa lik'hemik'hale tse ka sehloohong | Ni | Phomola | 55.0~61.0 | Phomola | 34.0~37.0 | 30.0~34.0 |

| Cr | 20.0~23.0 | 15.0 ~ 18.0 | 28.0~31.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤1 | Phomola | ≤1 | Phomola | Phomola | |

| Mocheso o Phahameng (ºC) | 1200 | 1150 | 1250 | 1100 | 1100 | |

| Resistance Temperature to correct coefficient.(CT) | 1.09±0.05 | 1.11±0.05 | 1.18±0.05 | 1.04±0.05 | 1.06±0.05 | |

| Sebaka se qhibilihang (ºC) | 1400 | 1390 | 1380 | 1390 | 1390 | |

| Resistivityρ20ºC(10-6Ω.m) | 800ºC | 1.008 | 1.078 | 1.028 | 1.188 | 1.173 |

| 1000ºC | 1.014 | 1.095 | 1.033 | 1.219 | 1.201 | |

| 1200ºC | 1.025 | 1.043 | ||||

| Boleng ba bophelo bo potlakileng | Tem.(ºC) | 1175 | 1100 | 1200 | 1050 | 1050 |

| hora(h) | ≥110 | ≥100 | ≥110 | ≥100 | ≥100 | |

| Matla a khoheli (g/cm3) | 8.40 | 8.2 | 8.1 | 7.90 | 7.90 | |

| Elongation(%) | ≥25 | ≥25 | ≥20 | ≥20 | ≥20 | |

| Thermal(kj/mhºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Mocheso o khethehileng(20ºC)j/g.ºC | 0.440 | 0.494 | 0.461 | 0.500 | 0.500 | |

| Eketsa matla (20 ~ 1000ºC) α*10-6ºC | 18.0 | 17.0 | 17.1 | 19.0 | 19.0 | |

| Matla a ho tiea(kg/mm2) | >85 | >85 | >85 | >85 | >85 | |

| Ho kobeha kgafetsa(F/R) | >12 | >12 | >12 | >12 | >12 | |

| Microstructure | Austenitic | Austenitic | Austenitic | Austenitic | Austenitic | |