Rea u amohela liwebsaeteng tsa rona!

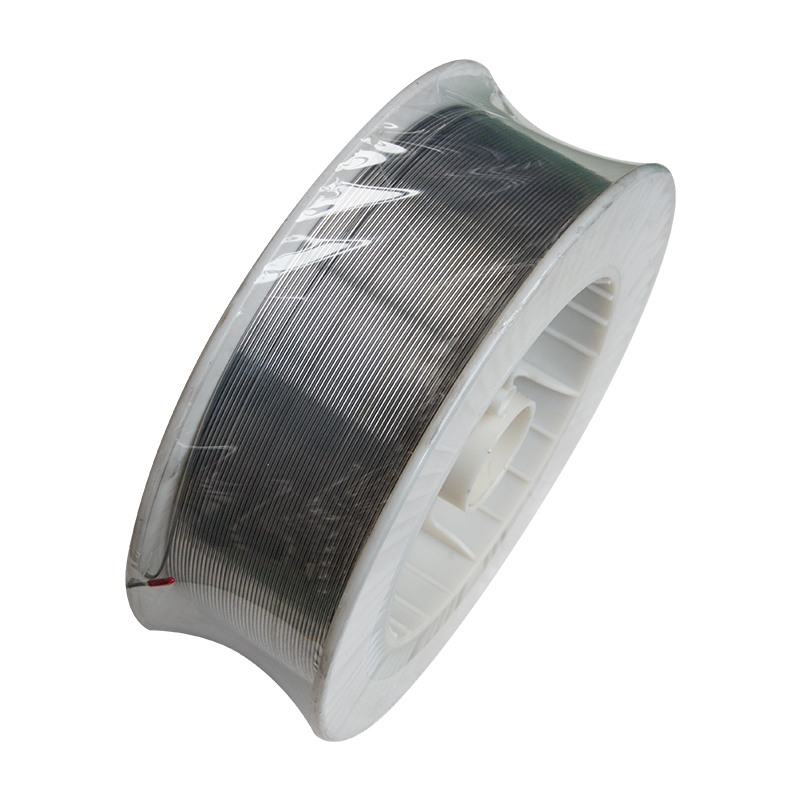

Khanyang 0.5mm Invar 36 Wire bakeng sa ho Tiisa Precision Sesebediswa

4J36 sebelisa oxyacetylene welding, motlakase arc welding, welding le mekhoa e meng.Kaha coefficient ea katoloso le metsoako ea lik'hemik'hale tsa motsoako e amana e lokela ho qojoa ka lebaka la tjheseletsa bakang phetoho motsoako motsoako, ho molemo ho sebelisa Argon arc tjheseletsa tjheseletsa filler tšepe ka ho khetheha e na le 0.5% ho 1.5% titanium, e le hore a fokotsa weld porosity le petsoha.

Sebopeho se tlwaelehileng%

| Ni | 35~37.0 | Fe | Bal. | Co | - | Si | ≤0.3 |

| Mo | - | Cu | - | Cr | - | Mn | 0.2 ~ 0.6 |

| C | ≤0.05 | P | ≤0.02 | S | ≤0.02 |

Coefficient ea katoloso

| θ/ºC | α1/10-6ºC-1 | θ/ºC | α1/10-6ºC-1 |

| 20 ~ 60 | 1.8 | 20-250 | 3.6 |

| Lilemo tse 20-40 | 1.8 | 20-300 | 5.2 |

| 20 ~ 20 | 1.6 | 20 ~ 350 | 6.5 |

| 20~-0 | 1.6 | 20-400 | 7.8 |

| 20-50 | 1.1 | 20-450 | 8.9 |

| 20 ~ 100 | 1.4 | 20 ~ 500 | 9.7 |

| 20 ~ 150 | 1.9 | 20 ~ 550 | 10.4 |

| 20 ~ 200 | 2.5 | 20-600 | 11.0 |

Tloaelehileng Thepa ea 'mele

| Boima ba 'mele (g/cm3) | 8.1 |

| Ho hanyetsa motlakase ho 20ºC(OMmm2/m) | 0.78 |

| Thempereichara ea ho hanyetsa (20ºC~200ºC)X10-6/ºC | 3.7~3.9 |

| Thermal conductivity, λ/ W/(m*ºC) | 11 |

| Curie ntlha Tc/ ºC | 230 |

| Elastic Modulus, E/Gpa | 144 |

| Mokhoa oa phekolo ea mocheso | |

| Annealing bakeng sa ho imolla khatello ea maikutlo | E futhumala ho 530 ~ 550ºC 'me u tšoare 1 ~ 2 h.Hatsela |

| annealing | E le ho felisa ho thatafala, e leng ho hlahisa ka mokhoa o batang, o batang oa ho taka.Anealing e hloka ho futhumatsoa ho 830 ~ 880ºC ka vacuum, tšoara 30 min. |

| Mokhoa oa ho tsitsisa |

|

| Mehato ya tlhokomelo |

|

Tloaelehileng Mechanical thepa

| Matla a tšepe | Elongation |

| Mpa | % |

| 641 | 14 |

| 689 | 9 |

| 731 | 8 |

Mocheso oa mocheso oa resistivity

| Boemo ba mocheso, ºC | 20-50 | 20 ~ 100 | 20 ~ 200 | 20-300 | 20-400 |

| aR/ 103 *ºC | 1.8 | 1.7 | 1.4 | 1.2 | 1.0 |

Ngola molaetsa wa hao mona mme o re romele wona